For 20 years

We focused on one thing

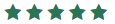

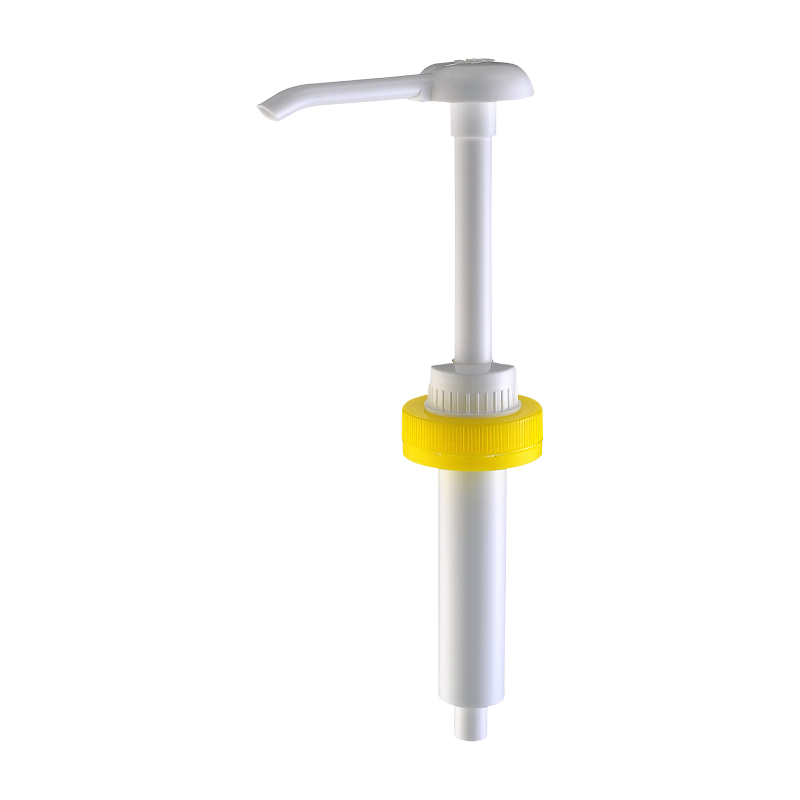

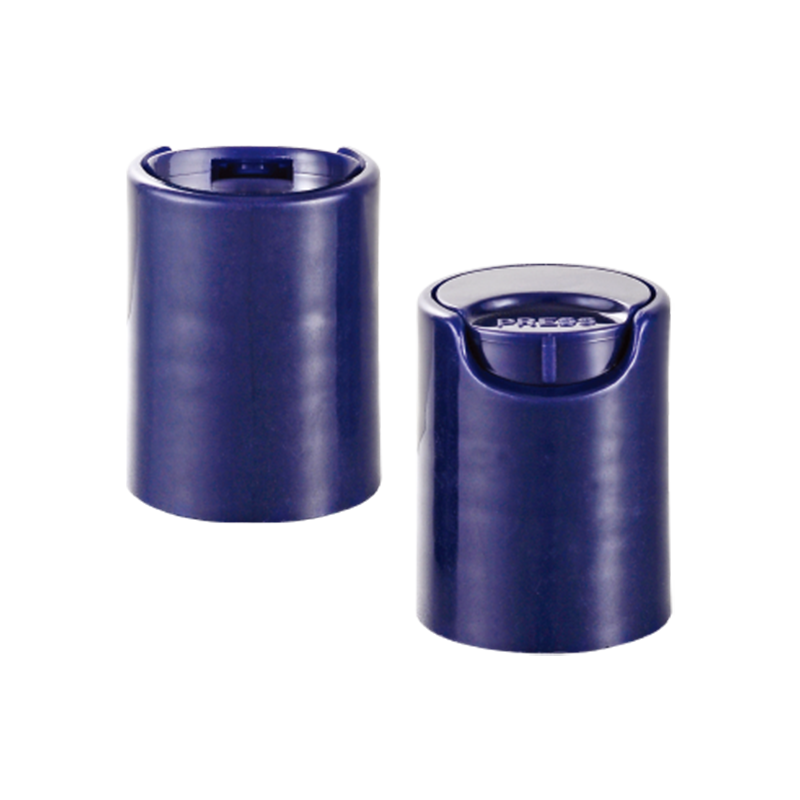

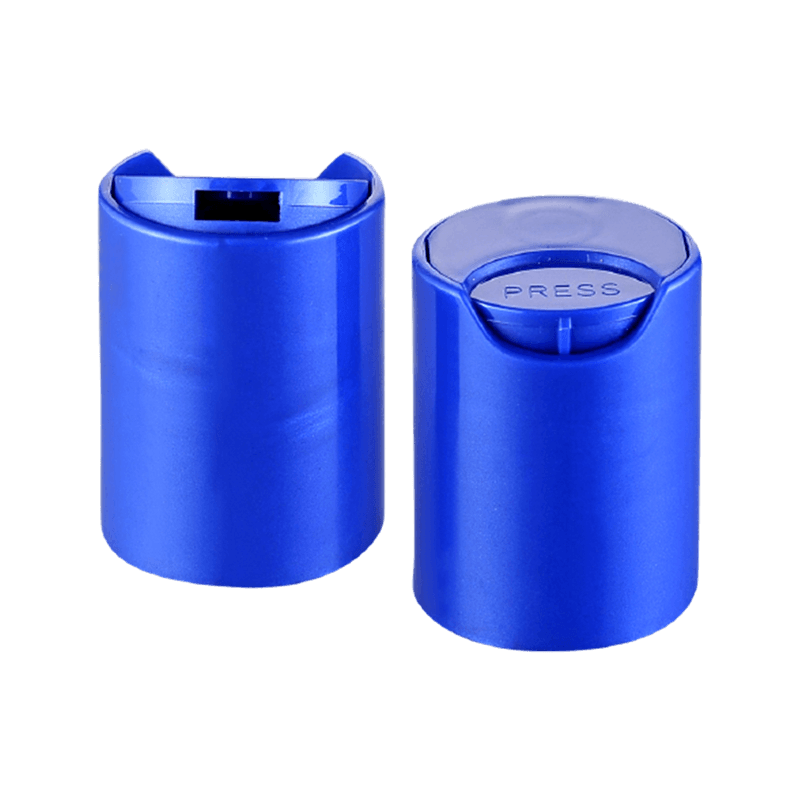

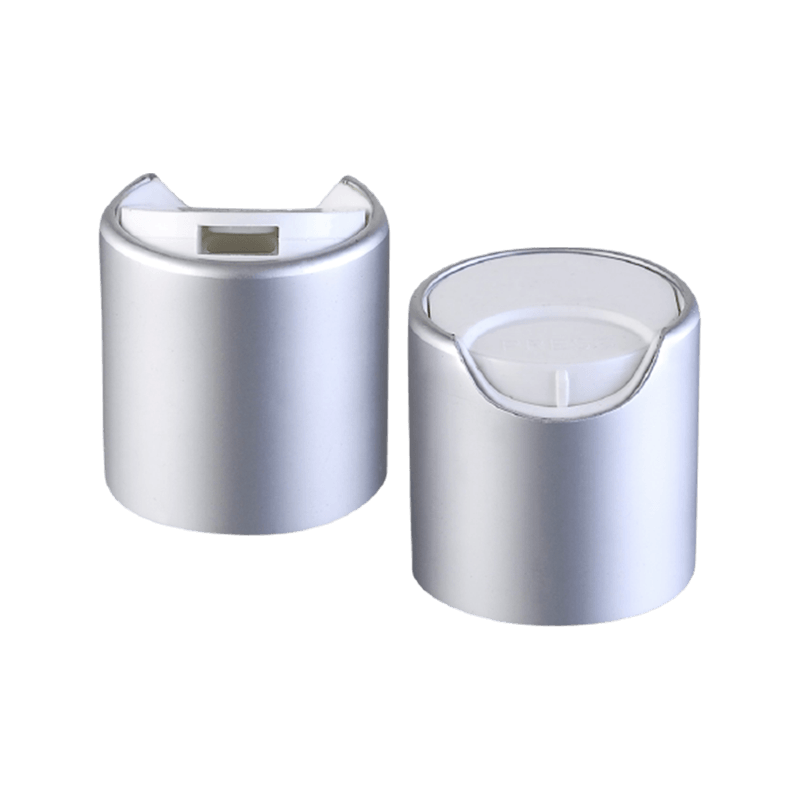

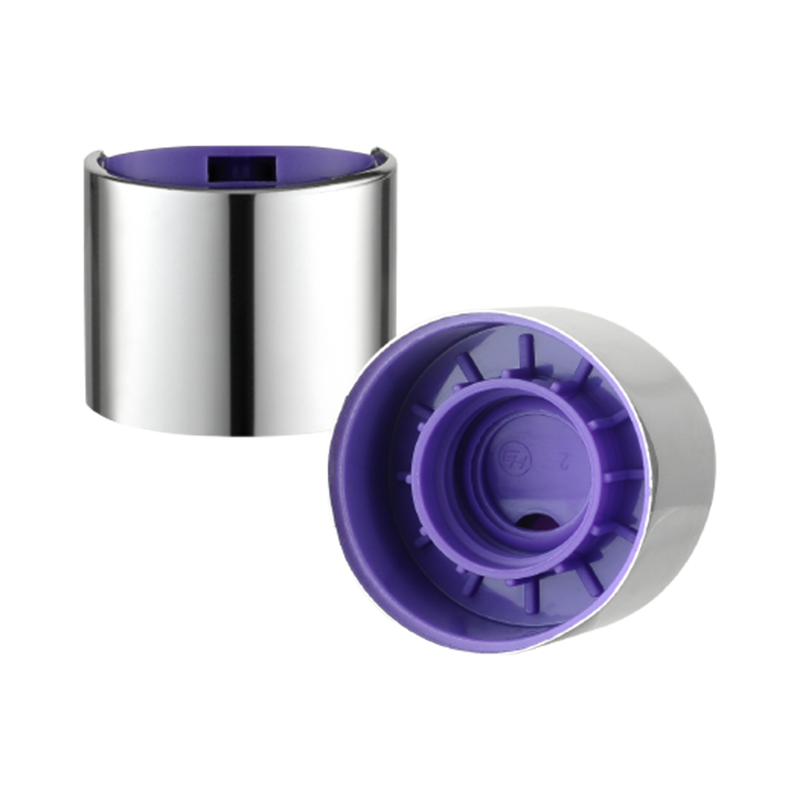

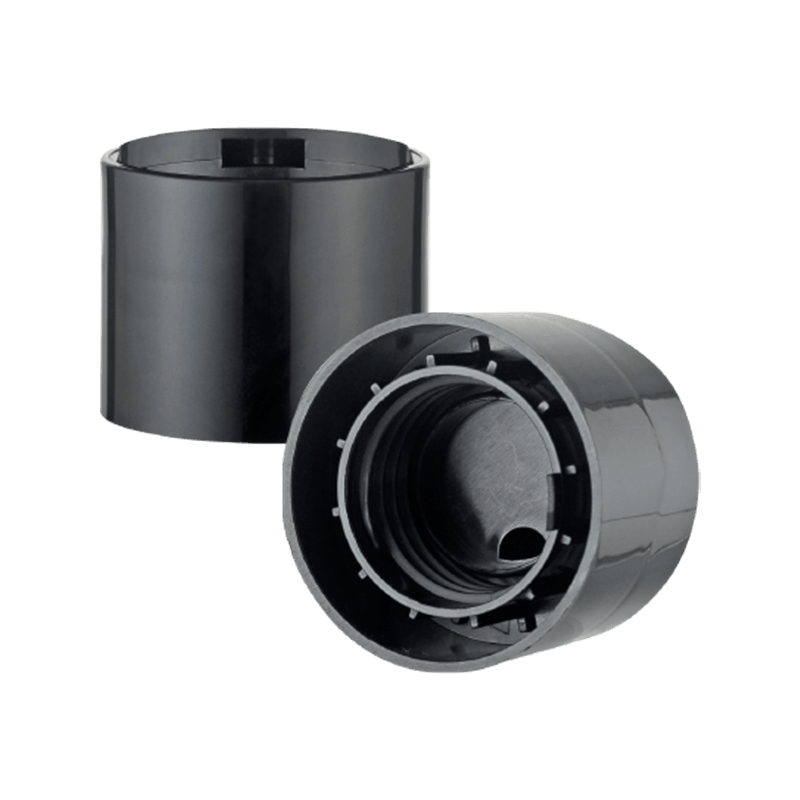

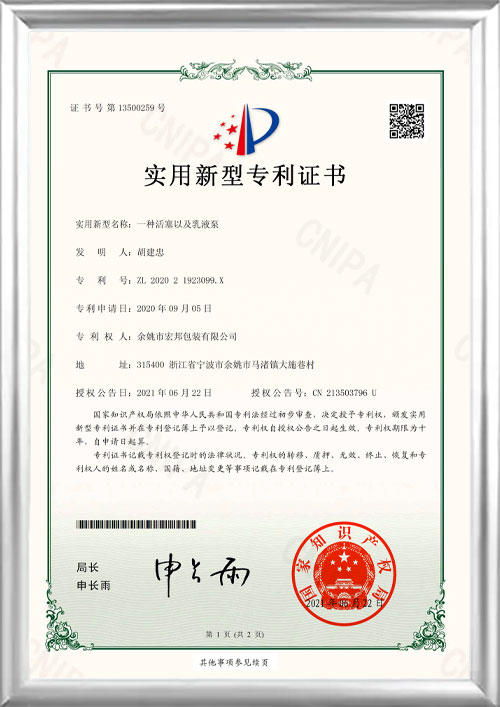

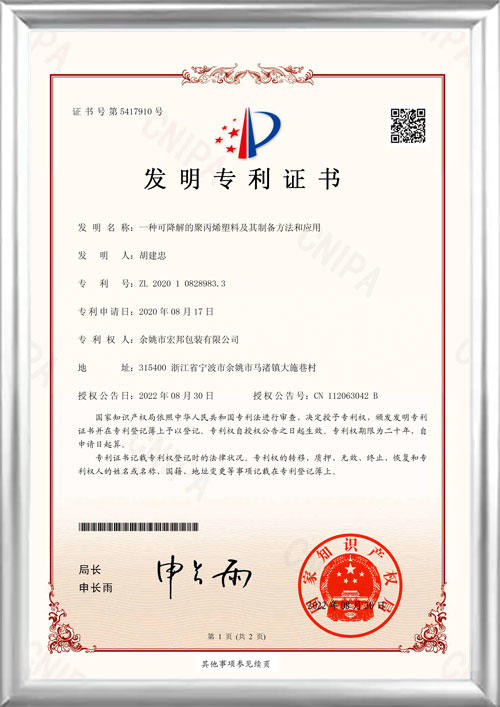

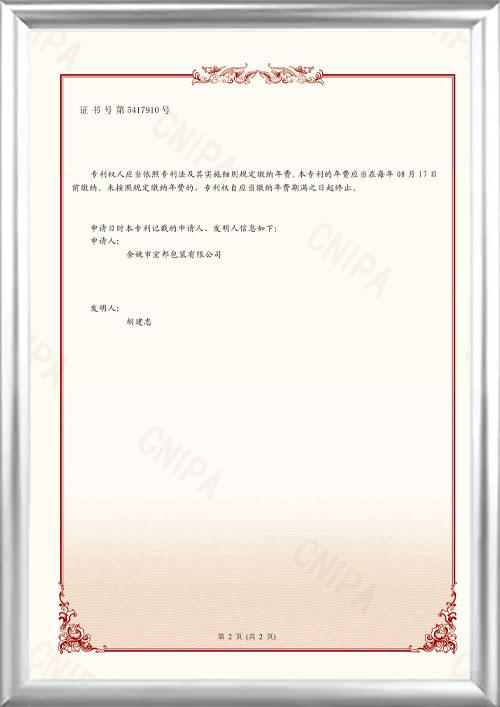

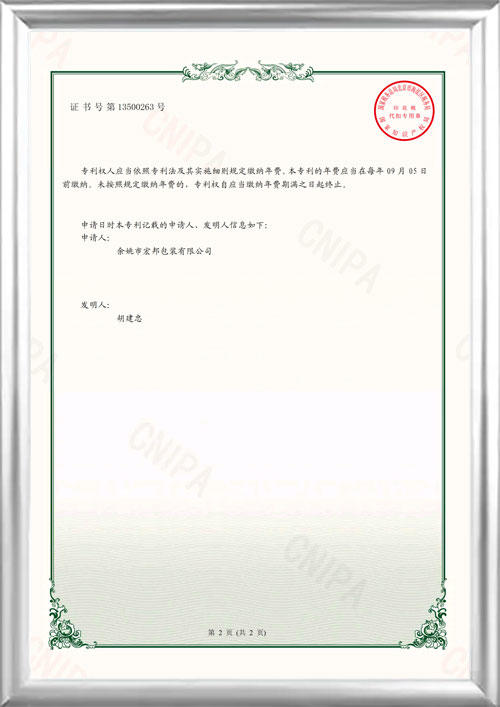

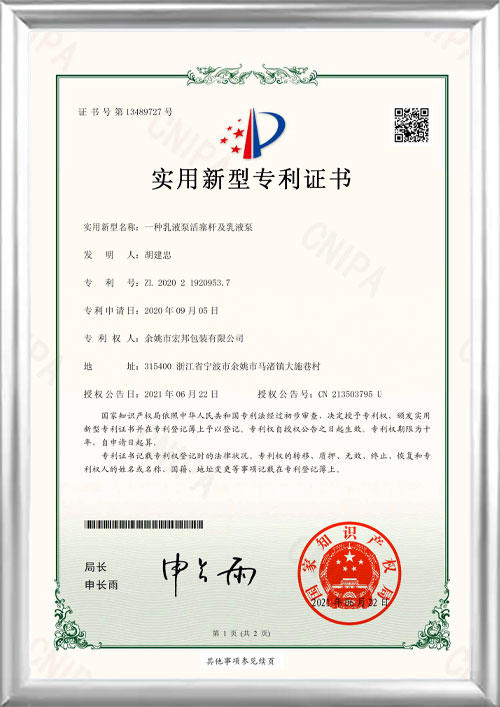

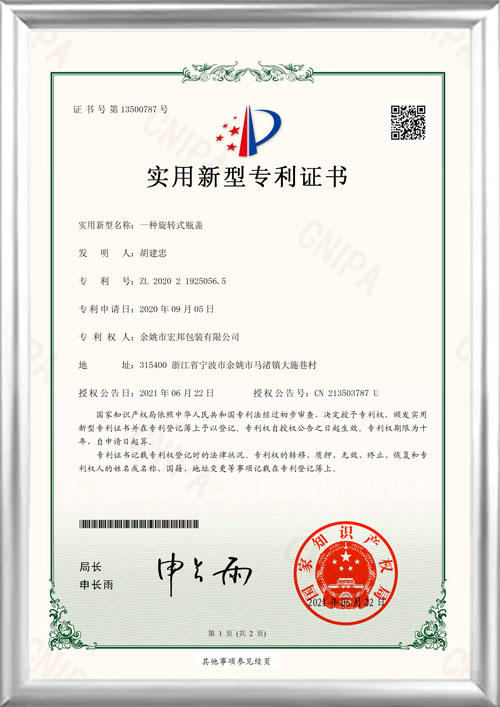

Yuyao Hongbang Packaging Co., Ltd., established in 2005, operates from a 13,000 square meter facility and serves as a comprehensive cosmetics packaging materials enterprise, encompassing research and development, production, and sales. Our primary product range includes plastic caps, plastic silicone valve caps, lotion pumps, spray pumps, and more. These products find applications in various sectors such as cleaning, personal care, medicine, and food.

Hongbang Packaging is professional China Plastic Cap Manufacturers and Wholesale Plastic Cap Factory. Over the course of more than a decade, our company has achieved an annual production capacity of 300 million units across diverse packaging options. We have garnered recognition from customers both at home and abroad by virtue of our professional and robust approach to technology research and development, standardized production management, rigorous quality control, and utilization of industry-leading production and testing equipment.

Moving forward, our company will continue to stride ahead, fostering innovation and providing customers with competitive products and services within the industry!

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Founded in 2005, has 13000 square meters of standard factory buildings, is a collection of research and development, production and sales in one of the cosmetics packaging materials enterprises.

Yuyao hongbang packaging co.,Ltd. Founded in 2005, has 13000 square meters of standard factory buildings, is a collection of research and development, production and sales in one of the cosmetics pack... -

How does Trigger Sprayer implement the liquid spray mechanism?

As a handheld liquid spray device, the Trigger Sprayer's liquid spraying mechanism is designed to achieve an efficient and uniform spray effect through the user's simple trigger operation. The design ... -

How does a trigger sprayer ensure the uniformity of spray?

As a common spray equipment, trigger sprayer needs to ensure the uniformity of spray during application to ensure its spraying effect and work efficiency. Achieving spray uniformity requires comprehen... -

What is the sealing performance of Silicone Valve Flip Top Cap?

The excellent sealing performance of the Silicone Valve Flip Top Cap comes from the unique characteristics of the silicone material and the carefully designed valve structure. Silicone material is fam... -

Next-generation clip-lock lotion pump enables efficient packaging in the personal care industry

As the personal care product market continues to develop and consumers improve product quality and user experience, innovation and performance optimization of packaging equipment have become the focus... -

How is the opening and closing mechanism of Flip Top Cap designed?

Flip Top Cap cleverly uses a flip-top structure. There is a flexibly flipable lid on the top, which is closely connected to the bottle cap body through a flexible connection. This design is not only b...

Expansion Of Industry Knowledge About This Category

2.Plastic Caps in Packaging

3.Challenges and Solutions in the Plastic Cap Industry

English

English 中文简体

中文简体 русский

русский Español

Español