For 20 years

We focused on one thing

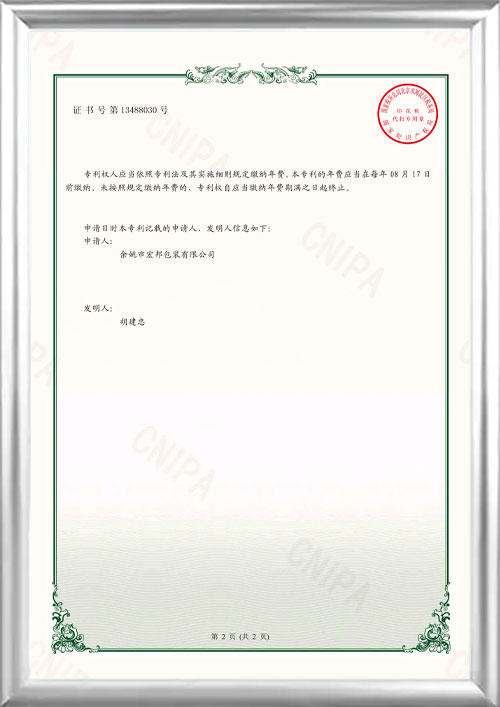

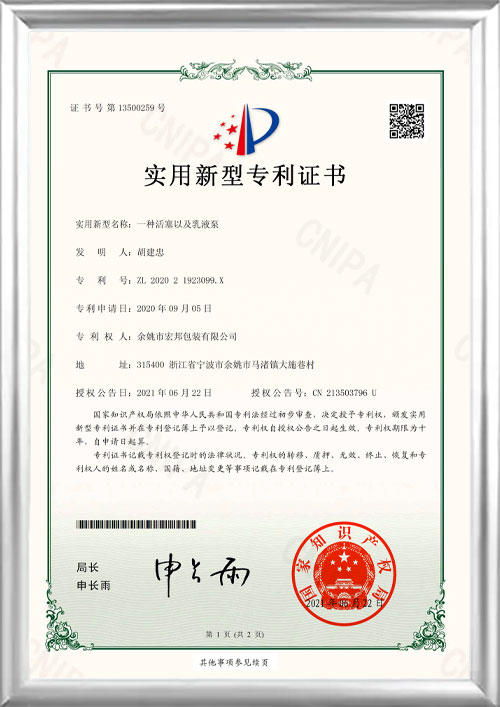

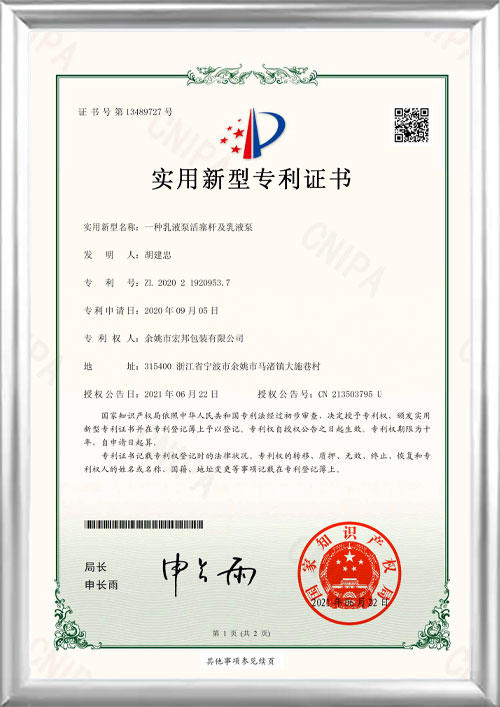

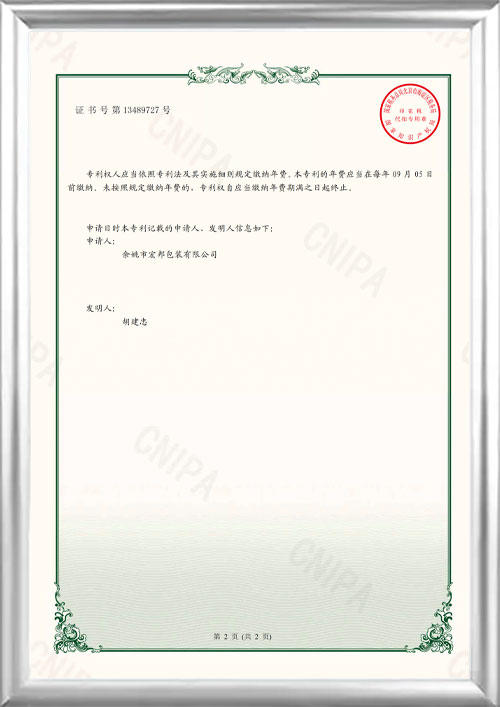

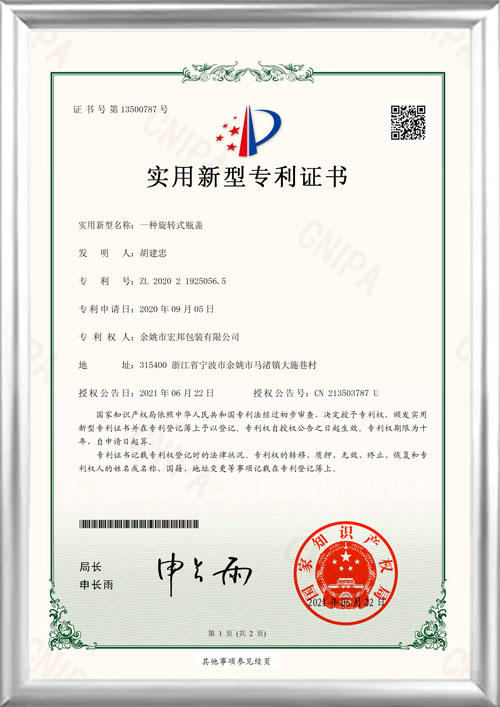

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Nail&Cleaning pump 0.6ML/T Suppliers and OEM Plastic Nail&Cleaning pump 0.6ML/T Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

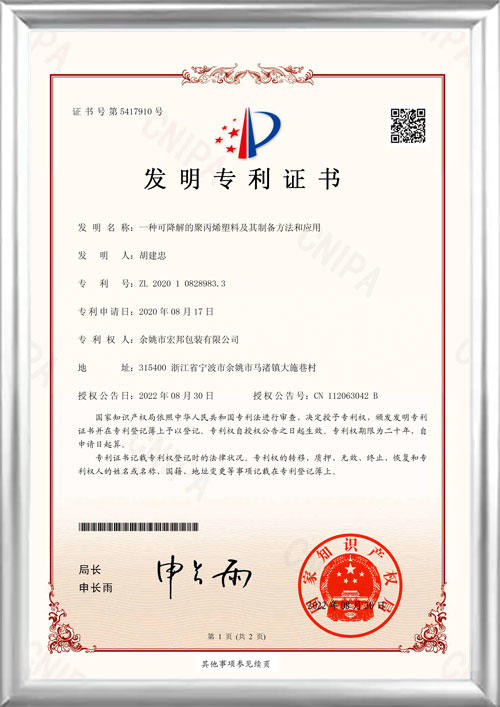

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Wide application and innovative design of silicone valve flip top cap

Jun 30,2025With the continuous change of consumer demand and the gradual popularization of environmental protection concepts, the packaging industry is constantly moving towards new heights in innovation and fun... -

Application Prospects of Lotion Pump in Personal Care and Cleaning Products

Jul 02,2025With the continuous improvement of consumers' requirements for convenience, hygiene and environmental protection, the application of lotion pump in personal care and cleaning products has gradually be... -

Importance of CRC child-resistant bottle caps in the family

Jun 25,2025With the increasing attention paid to children's safety in modern society, various protective measures have gradually become an indispensable part of family daily life. Especially for common container... -

From wine to cosmetics, Screw Cap is becoming the new favorite of the packaging industry

Jun 18,2025With the continuous innovation of the packaging industry, the traditional packaging form of Screw Cap is rapidly breaking through the low-end market and becoming an important packaging solution for ma... -

Environmental protection without compromising experience, Flip Top Cap achieves double breakthroughs

Jun 11,2025In the process of moving towards sustainable development goals globally, the packaging industry is ushering in a trend of innovation in which materials and design go hand in hand. As a component with ... -

Medium size plastic disc cover Q20-04 - providing high-quality packaging solutions for various industries

Jun 04,2025The Q20-04 plastic disc cover is made of PP (polypropylene) material. The chemical stability of PP material is very strong and can effectively resist the corrosion of various acids, alkalis, salts and...

Expansion Of Industry Knowledge About This Category

2.What are the key features of this Nail&Cleaning Pump 0.6ML/T?

English

English 中文简体

中文简体 русский

русский Español

Español