For 20 years

We focused on one thing

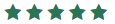

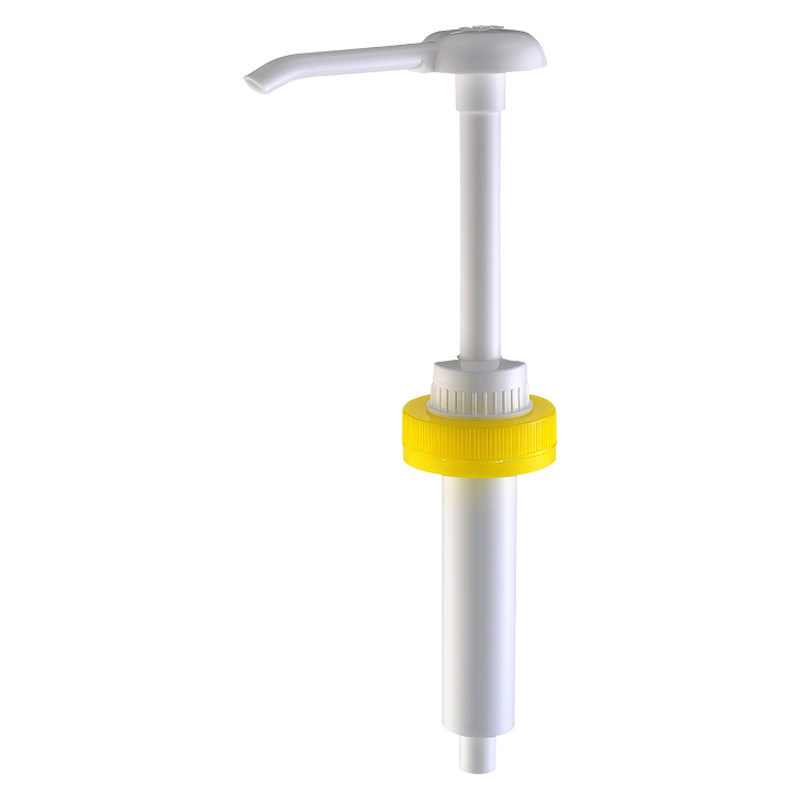

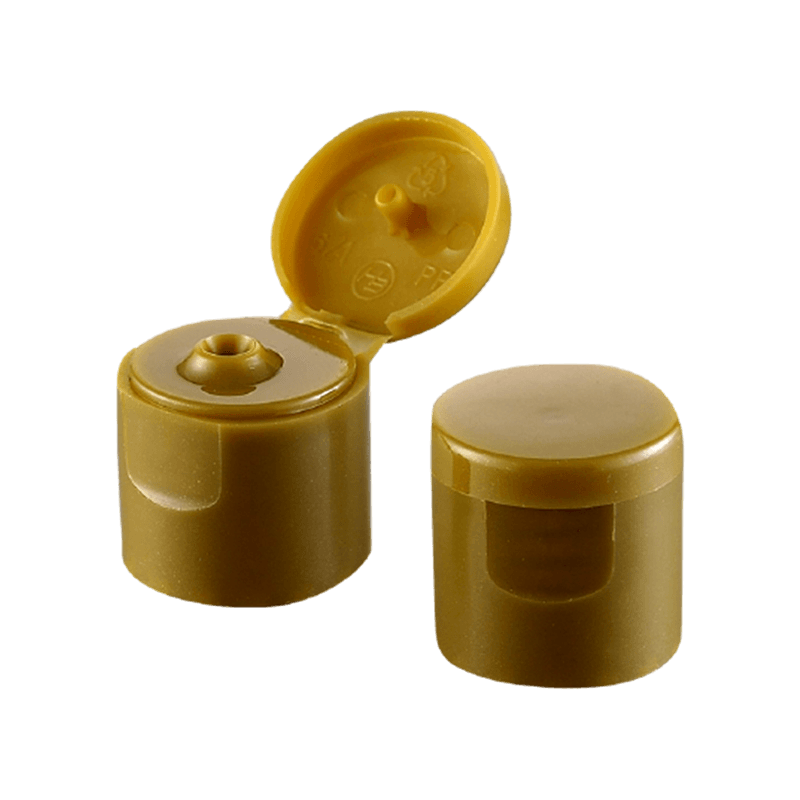

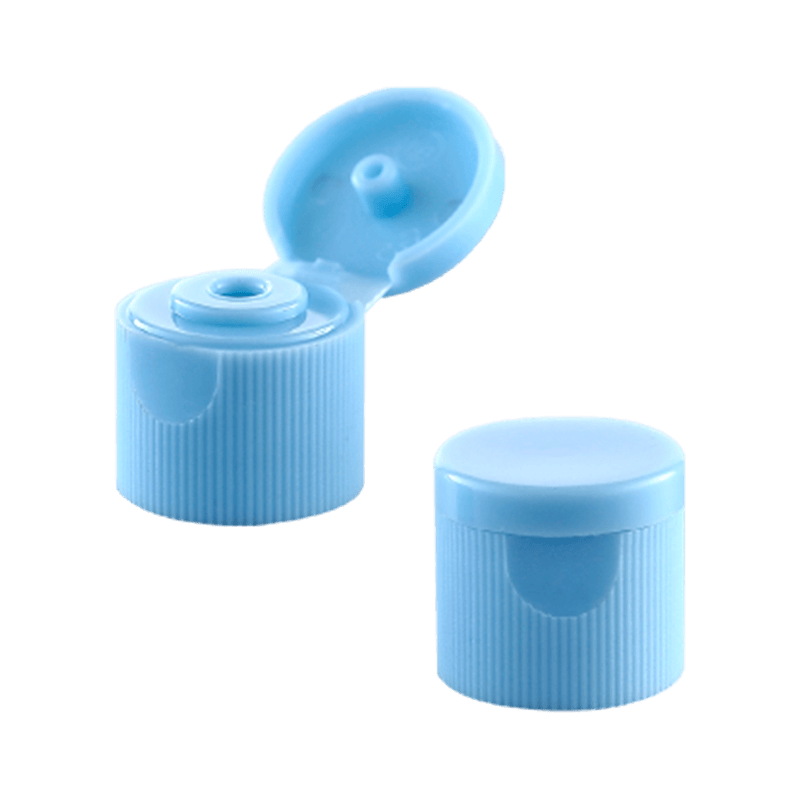

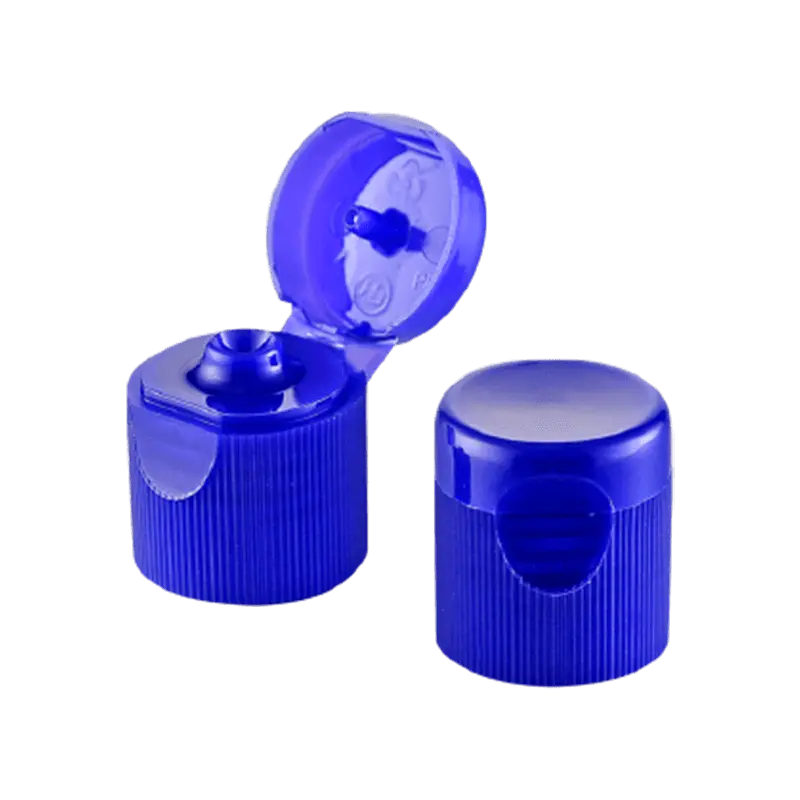

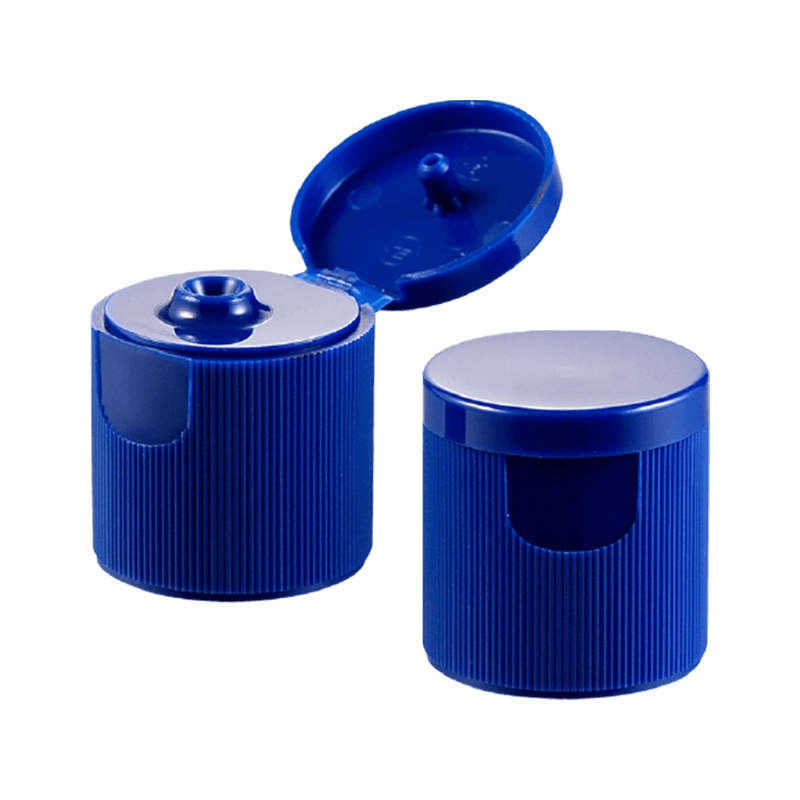

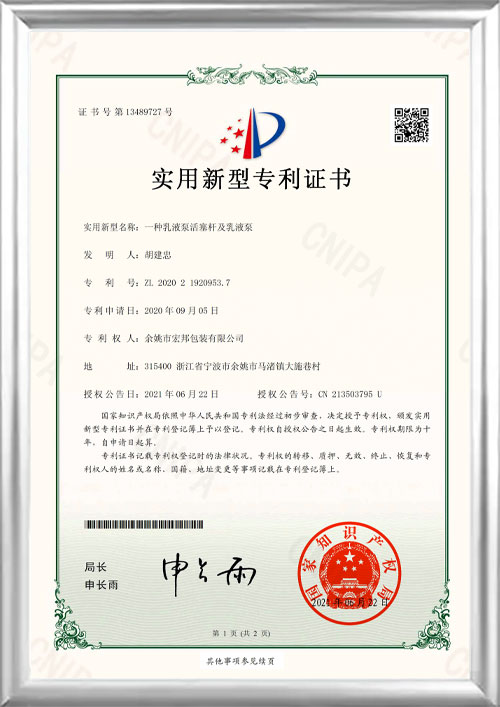

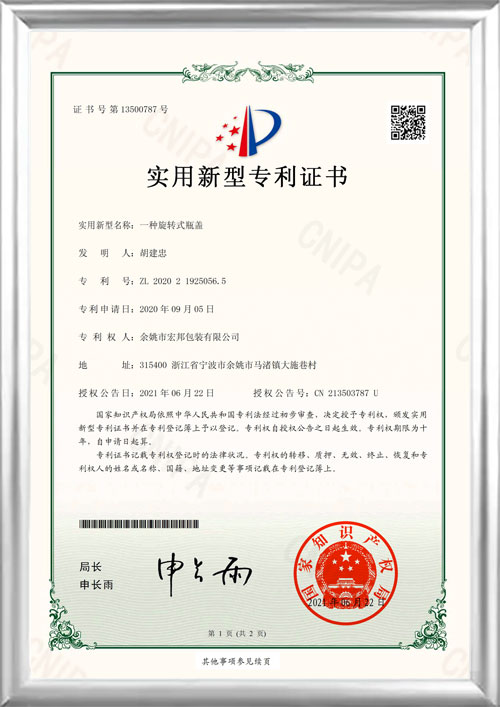

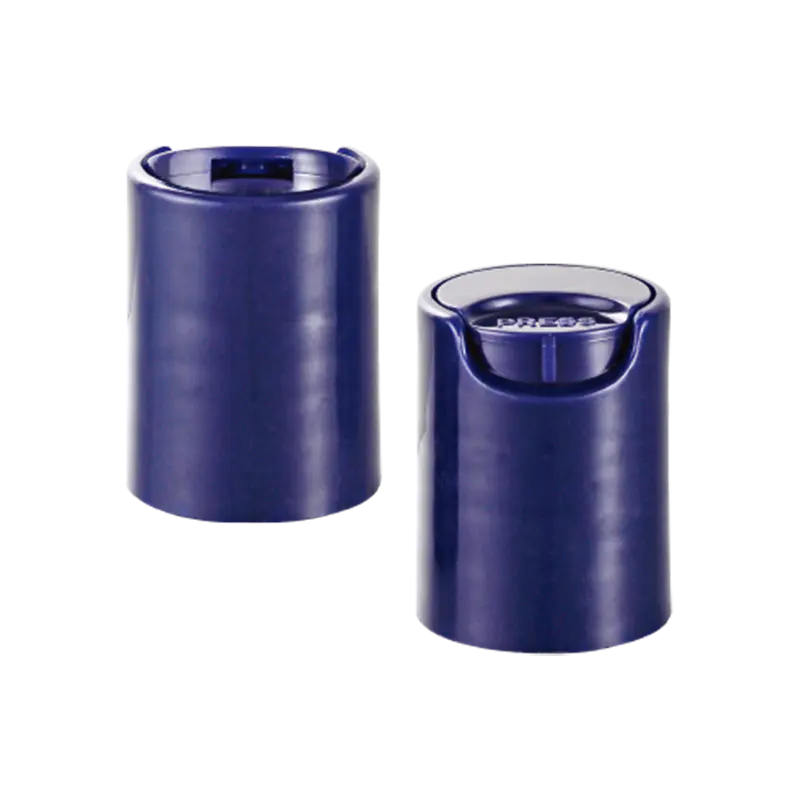

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials.

Hongbang Packaging is professional China Plastic Flip Top Cap Manufacturers and Wholesale Flip Top Cap Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

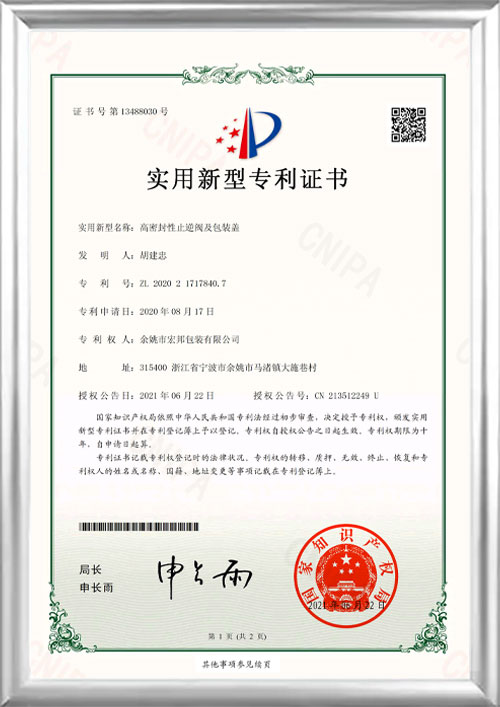

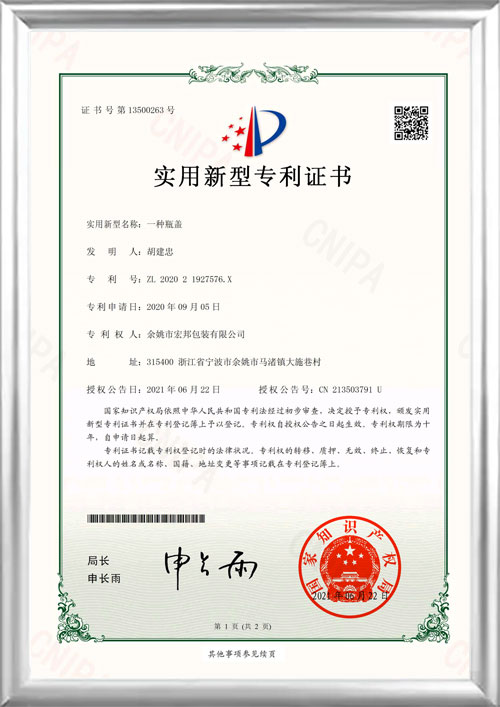

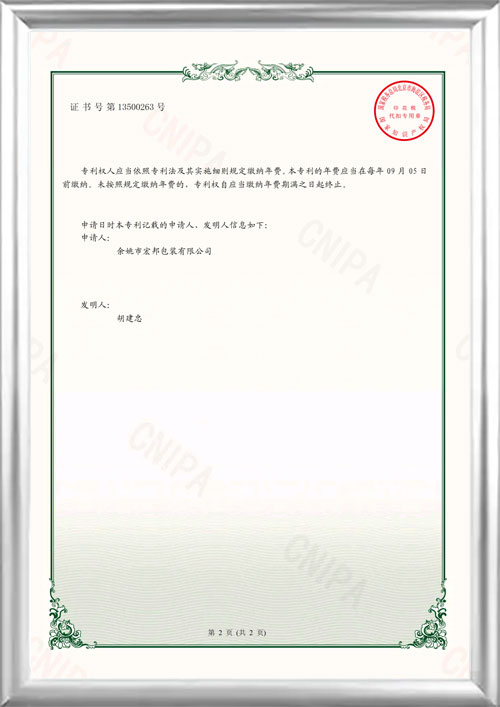

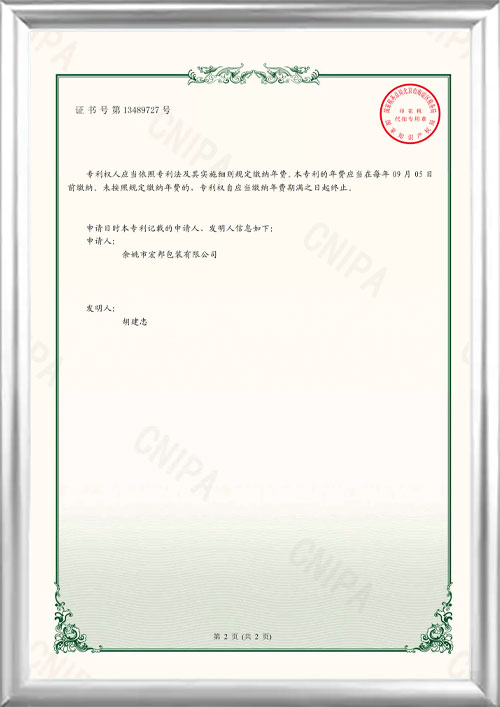

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

Flip Top Cap is a bottle cap design with a flip function, which is widely used in the packaging of various consumer goods. It is usually made of plastic materials such as PP and PE, and has good sealing and durability. Its main feature is that it is convenient for consumers to operate with one hand, and it is quick and convenient to use. The flip-top structure makes the opening and closing of the bottle cap very simple, especially suitable for fast-drinking bottled water, juice and tea beverages, etc., which can accurately control the flow rate and reduce waste and overflow.

Flip Top Cap is also widely used in the packaging of cosmetics, cleaning products and condiments due to its sealing performance. Cosmetics such as shampoo and shower gel often use this design to improve convenience and avoid product leakage. For products such as detergents and laundry detergents, the flip-top design can also effectively prevent leakage and avoid unnecessary pollution to users or the surrounding environment. In the condiment industry, bottled products such as soy sauce and ketchup also often use this bottle cap to control the pouring amount and reduce waste.

2.Market Trends and Innovation

With increasingly stringent environmental regulations and increasing consumer demand for sustainable packaging, the market trend of Flip Top Cap is changing. More and more companies are adopting recyclable materials such as PET and biodegradable plastics to meet environmental challenges. Especially in the field of cosmetics and beverage packaging, brands are gradually inclined to use environmentally friendly materials, which not only meets environmental requirements, but also enhances the brand's social responsibility image and attracts more environmentally conscious consumers.

Consumers are also increasingly demanding smart and convenient packaging. For example, many new Flip Top Cap designs have added easy-open functions, child-proof misuse designs, and better sealing technology. These innovations not only enhance the user experience, but also make the bottle cap safer and easier to operate.

With the intensification of market competition, personalized customization has become a major trend for brands. Many companies have begun to provide customized Flip Top Caps, including colors, patterns, materials, and printing designs, to meet brand marketing needs and enhance consumer brand loyalty. This trend is particularly applicable to the cosmetics and high-end beverage industries, where brands attract target markets through unique designs.

3.Production Process and Challenges

Since its establishment in 2005, Yuyao Hongbang Packaging Co., Ltd. has been committed to providing high-quality packaging solutions, especially in the production of Flip Top Cap, and has accumulated rich experience. The company produces more than 200 sets of precision molds each year to meet the needs of different customers for high-end packaging. With its sophisticated multi-cavity injection molding technology and advanced production equipment, Yuyao Hongbang can ensure that Flip Top Cap has good sealing, stable quality and high precision during the manufacturing process.

In the production process of Flip Top Cap, Yuyao Hongbang focuses on quality control and optimization of production processes. Through precise mold design and strict production processes, defects in the product during the production process can be effectively avoided, ensuring that each bottle cap meets high standards. The company uses advanced injection molding technology to accurately control the size, sealing and durability of each product.

Although Yuyao Hongbang has made many achievements in the production process, it still faces some challenges. First of all, environmental protection issues are the focus of the company's attention. How to use more environmentally friendly materials and processes while ensuring product quality is an ongoing challenge. The company has begun to use recyclable plastics and biodegradable materials, and is constantly exploring more environmentally friendly solutions. Secondly, the expansion of production scale and diversified market demand have also made it an important task for the company to find a balance between maintaining high production efficiency and reducing production costs. To this end, Yuyao Hongbang has improved overall production efficiency and cost-effectiveness by optimizing production processes, increasing the service life of molds, and shortening production cycles.

English

English 中文简体

中文简体 русский

русский Español

Español