For 20 years

We focused on one thing

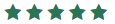

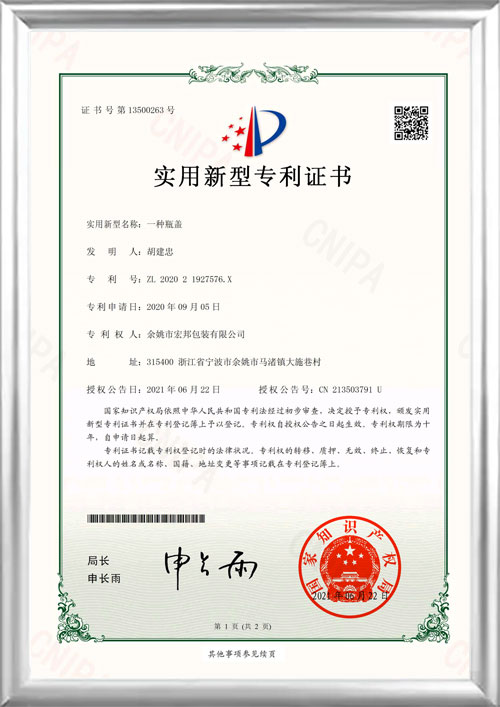

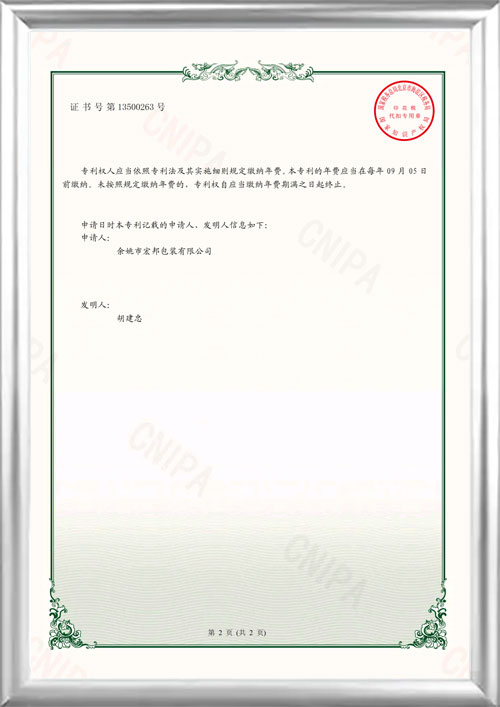

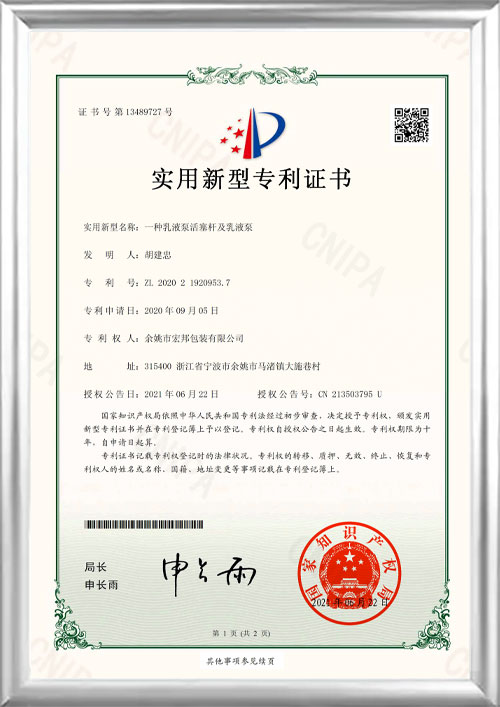

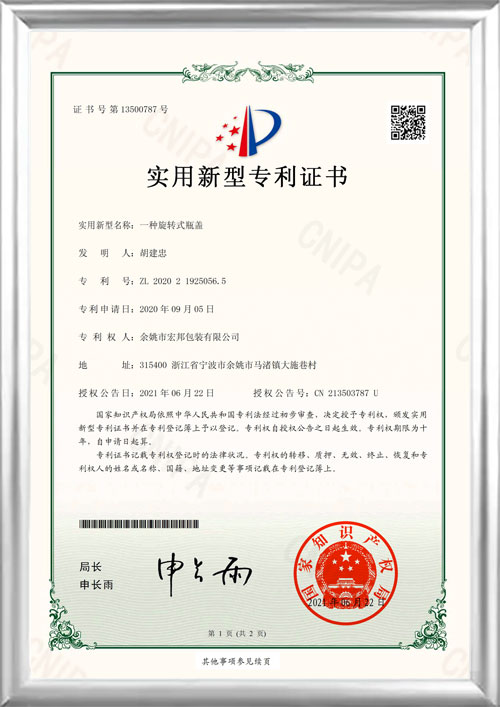

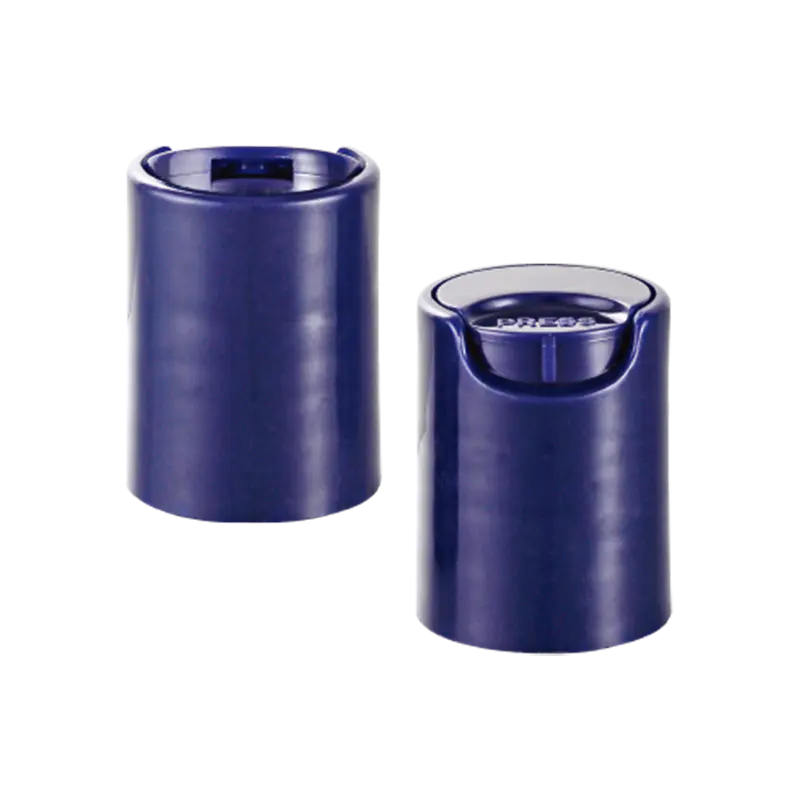

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Plastic Trigger Sprayer Suppliers and OEM Trigger Sprayer Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

A trigger sprayer is a device commonly used for dispensing liquids. It is typically mounted on the mouth of a plastic bottle and dispenses the liquid by manually depressing a trigger. Its primary function is to evenly distribute the liquid in the form of a fine mist or spray. It is widely used in household cleaning, gardening, cosmetics, and industrial applications.

The operating principle of a trigger sprayer is relatively simple, relying on a mechanical trigger mechanism. The user depresses the trigger, pushing an internal piston and forcing liquid into the nozzle through a tube (usually a hose running from the bottom of the bottle to the nozzle). The nozzle design typically allows for adjustable spray flow and pattern, allowing users to choose from a fine mist, a powerful jet, or a wide spray pattern to meet different liquid application requirements. Some high-end sprayers allow the nozzle to be rotated or adjusted as needed to change the spray pattern to suit different environments and usage scenarios.

The piston system within a trigger sprayer also plays a crucial role in its operation. It helps propel the liquid and increase pressure, ensuring a smooth spray. Some specially designed sprayers may incorporate airflow enhancement or secondary pressure systems to increase spray distance or enhance spray uniformity.

Key Components and Materials of Trigger Sprayers

A trigger sprayer consists of several key components, each of which performs a specific function to ensure effective and long-lasting use. The most basic components include the trigger, nozzle, tubing, cap, and piston. These components are typically manufactured from durable and environmentally friendly materials.

Trigger: The trigger is the operating part of the sprayer, controlling the spraying of the liquid. By pressing the trigger, the attached piston pushes the liquid toward the nozzle. Modern sprayer designs take ergonomics into consideration, and triggers are often designed to be more comfortable in the hand to prevent fatigue during prolonged use.

Nozzle: The nozzle is the part where the liquid exits and contacts the air. Nozzle design is crucial, determining the atomization of the sprayed liquid. Nozzles come in different apertures to adjust the spray particle size, spray angle, and flow rate. Some sprayers also feature adjustable nozzles, allowing users to select different spray patterns, from a fine mist to a wide-area spray.

Hose: This is the long tube connecting the sprayer to the bottle. It draws the liquid from the bottle and directs it to the nozzle. The length of the tube is typically designed based on the height of the bottle to ensure maximum liquid extraction.

Piston: The piston is the "heart" of the sprayer. It generates pressure when the trigger is pressed, pushing the liquid into the nozzle. The piston material needs to be wear-resistant and resilient to ensure it resists damage after long-term use.

Bottle Cap: The bottle cap connects the sprayer to the container and needs to ensure a tight seal to prevent liquid leakage.

Plastics are the primary material used in sprayers due to their lightness, corrosion resistance, ease of molding, and low cost. Some high-end sprayers may also use metal components such as stainless steel or aluminum to enhance the product's durability and aesthetics. In some designs, the seal between the sprayer and the bottle opening may be made of rubber or soft plastic to further improve the seal and prevent leaks.

Trigger Sprayer's Widespread Applications and Market Demand

Trigger sprayers, as efficient liquid dispensing tools, are widely used in a variety of fields, including household cleaning, gardening, cosmetics, personal care, and industrial applications. With increasing consumer demand for environmentally friendly, sustainable, and efficient design, the market demand for trigger sprayers is also growing.

In the household cleaning industry, trigger sprayers are used to dispense products such as cleaners, disinfectants, and air fresheners. The sprayer's design ensures uniform coverage of the cleaning solution across surfaces, improving cleaning effectiveness and reducing liquid waste. For example, when cleaning the kitchen or bathroom, users can easily apply cleaning solution with a sprayer without excessive waste. This precise liquid control is particularly suitable for applications that require fine distribution of cleaning solutions or disinfectants, eliminating the resource waste associated with traditional cleaning methods.

In gardening, sprayers are primarily used to apply plant protection solutions, herbicides, and nutrients to promote healthy plant growth. Compared to traditional spraying methods, trigger sprayers provide more even liquid distribution, reducing waste and increasing liquid utilization. This is particularly important for environmental protection, as excessive chemical use can negatively impact ecosystems. A growing number of hobbyists and professional gardeners are turning to sprayers for precise pesticide and watering applications.

Sprayers also play a key role in the cosmetics and personal care sectors. Especially for dispensing facial mists, hair care products, and various styling sprays, sprayers provide uniform atomization, allowing consumers to easily and evenly apply the products. For example, moisturizing mists, with their fine atomization, penetrate the skin quickly and provide deep hydration. Furthermore, the precise dispensing of lotions and perfumes also benefits from trigger sprayers, which prevent overdosing.

In the industrial sector, trigger sprayers are widely used for dispensing products such as chemicals, cleaning fluids, lubricants, and disinfectants. These applications often require sprayers with strong corrosion resistance and high liquid dispensing accuracy. Trigger sprayers help companies control liquid flow while reducing waste and operator errors, thereby improving work efficiency.

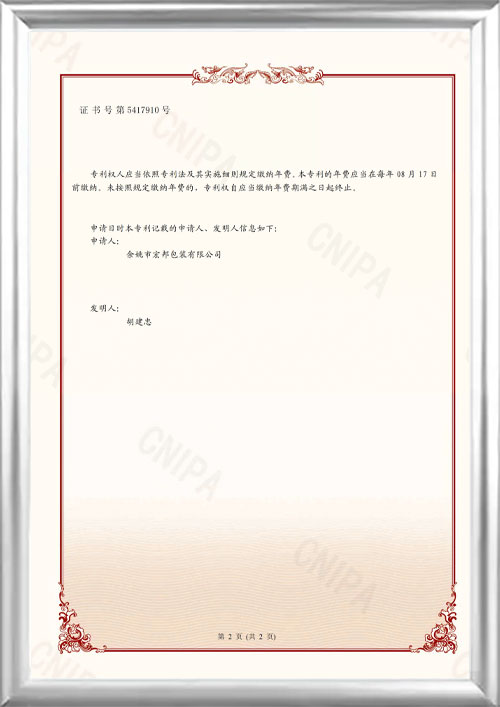

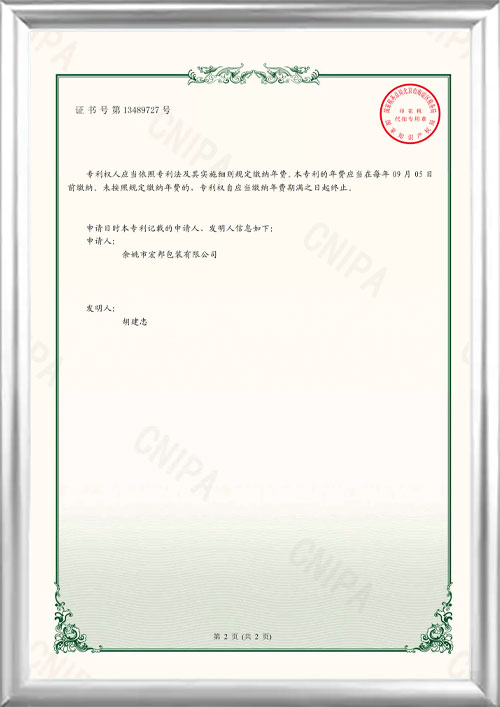

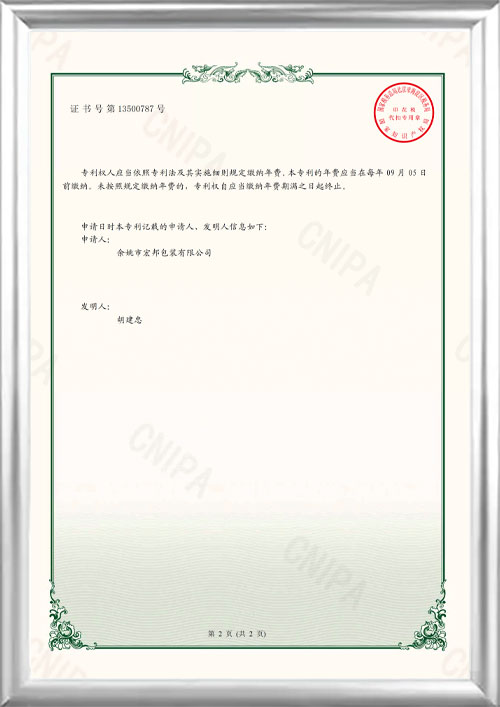

Yuyao Hongbang Packaging Co., Ltd., a manufacturer specializing in plastic packaging solutions, has been committed to providing a wide range of packaging products, including trigger sprayers, since its establishment in 2005. As a comprehensive manufacturer, Yuyao Hongbang Packaging Co., Ltd. boasts a mature production chain and accumulated technical expertise in sprayer manufacturing, encompassing multiple steps, including product design, mold development, automated injection molding, and assembly, ensuring efficient production and superior product quality.

The company is committed to providing customized packaging solutions, particularly for the personal care, cleaning products, cosmetics, and pharmaceutical packaging industries. Driven by innovation, Yuyao Hongbang Packaging Co., Ltd., through its dedicated R&D team, continuously optimizes the design and functionality of its sprayers to meet evolving market demands. In addition to prioritizing functionality, Hongbang Packaging also prioritizes environmental protection and sustainability, gradually increasing the use of environmentally friendly materials such as PCR and TPE. This not only ensures product reliability and safety, but also reduces environmental impact.

Although trigger sprayers are widely used in daily life, they may encounter some common problems during use. Understanding how to solve these problems can extend the life of the sprayer and ensure stable performance.

Uneven spray or clogged nozzle: If the sprayer's spray pattern is uneven, it may be because the nozzle is clogged with impurities or residue. This often occurs when there are sediment or particles in the liquid. The solution is to clean the nozzle regularly with warm water or a suitable detergent to thoroughly remove the blockage.

Leakage: Sprayer leaks are often caused by a poor seal at the bottle cap or deterioration of the bottle cap. Inspect the bottle cap and seal for integrity. If they are deteriorated or damaged, replace them with a new one to prevent leaks.

Difficulty operating the trigger: If the trigger is difficult to press, the internal piston or spring may be stuck. In this case, try gently tapping the sprayer to help loosen the stuck part, or lubricate the trigger and piston with lubricant.

Liquid does not flow out: If the liquid does not flow out when you press the trigger, it may be due to a blockage in the pipe or nozzle, or the viscosity of the liquid itself is too high. In this case, you can clean the pipe to ensure that the liquid can flow smoothly.

English

English 中文简体

中文简体 русский

русский Español

Español