For 20 years

We focused on one thing

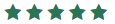

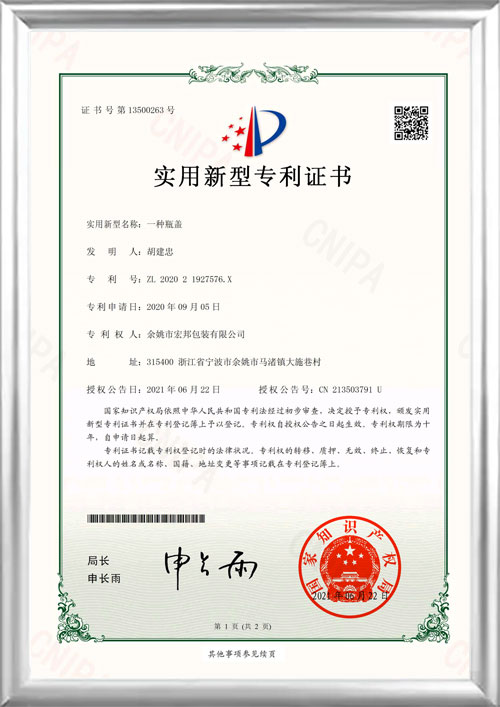

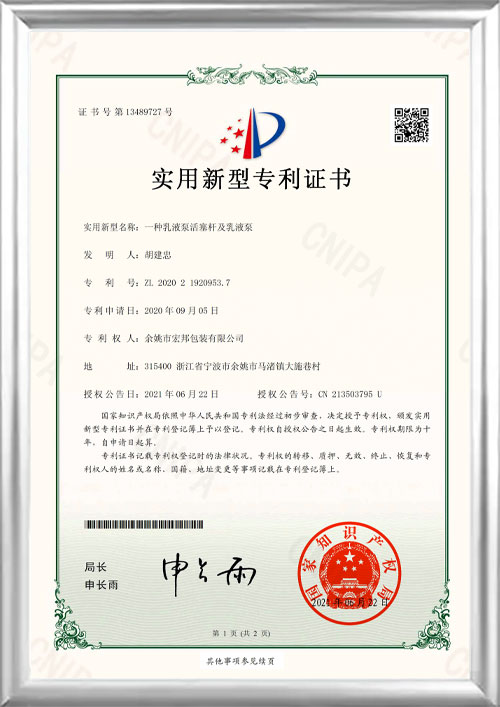

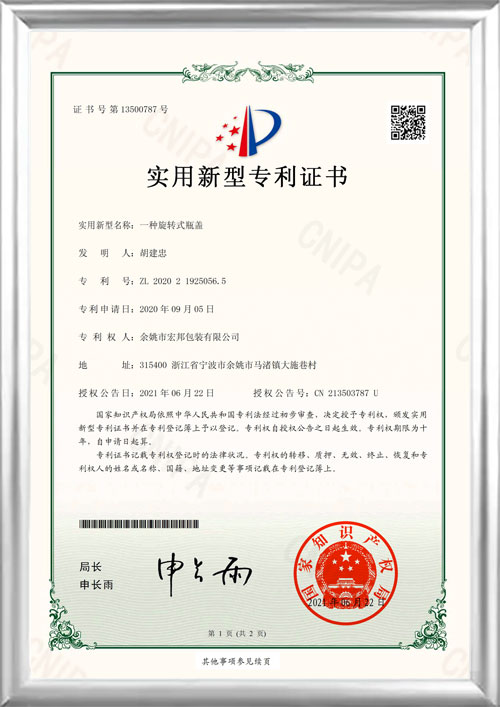

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Plastic Screw microsprayer 0.12ML/T Suppliers and OEM Screw microsprayer 0.12ML/T Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

The core technological advantage of the Screw Microsprayer 0.12ML/T lies in its high-precision liquid control and micron-level atomization. These features make it an outstanding choice for applications in the pharmaceutical, cosmetic, and agricultural industries, enabling precise spraying and efficient liquid distribution.

One of the design hallmarks of the Screw Microsprayer is its precise liquid spray control. Each spray delivers 0.12ml of liquid, meaning the device delivers a very precise amount of liquid. This precise liquid control is crucial for applications requiring precise metering of liquids, such as pharmaceutical spraying and agricultural pesticide spraying. Precise liquid volume control not only ensures efficient resource utilization and reduces waste, but also significantly improves spraying effectiveness and efficiency, enhancing product functionality and affordability.

Another key technical feature is its atomization performance. The Screw Microsprayer atomizes liquid into extremely fine micron-level droplets, which is crucial for improving product absorption efficiency and performance. In the pharmaceutical industry, micron-sized spray particles facilitate drug absorption. This micronized form, particularly for spray-type medications, allows for even coverage and penetration of the skin or respiratory tract, ensuring maximum efficacy. In the cosmetics industry, a fine spray evenly distributes products, reduces buildup on the skin, and provides a more balanced treatment.

The Screw Microsprayer also boasts exceptional durability and stability. Made from corrosion-resistant and high-temperature-resistant high-performance materials, it operates reliably and consistently in diverse environments, adapting to extreme temperature and humidity fluctuations. This stability is ideal for long-term use, particularly in fields such as agriculture and environmental protection, which require frequent operation. The device's corrosion resistance is particularly suitable for chemical liquid spraying, ensuring stable performance over extended use and reducing maintenance costs.

The Screw Microsprayer's design also offers flexibility, allowing for custom adjustments to parameters such as spray angle, spray intensity, and particle size. This flexibility allows the device to be adapted to meet diverse application requirements, from fine medical spraying to large-scale agricultural spraying. This microspray device isn't limited to a single industry; it has broad cross-industry application potential.

Due to its superior spray technology and liquid control capabilities, the Screw Microsprayer 0.12ML/T has been widely used in various industries, particularly in healthcare, cosmetics, agriculture, and environmental protection. Its precise spraying technology and efficient liquid distribution effectively improve product quality, performance, and operational efficiency across various sectors.

In the pharmaceutical industry, the micron-level spray quality of the Screw Microsprayer is crucial for precise drug distribution and efficient absorption. In respiratory therapy, the absorption efficiency of inhaled medications depends largely on the particle size of the spray. Traditional nebulizers often struggle to ensure uniform drug distribution in the respiratory tract. The Screw Microsprayer, however, disperses the drug into tiny particles through precise atomization, thereby increasing drug absorption. Whether treating asthma, chronic obstructive pulmonary disease (COPD), or other respiratory conditions, a fine spray helps improve drug efficacy and reduce drug waste. Topical spraying is also a common treatment for skin diseases. The Screw Microsprayer evenly distributes medication to the area in need, preventing a thick coating on the skin surface, thereby reducing side effects and enhancing treatment effectiveness.

In the cosmetics industry, the application of microspray technology is particularly important, especially in the design of spray-on skincare products and fragrances. The fine spray of the Screw Microsprayer ensures that the liquid evenly coats the skin, preventing excess waste. For skincare products that require efficient absorption, such as spray-on toners or sunscreens, the microspray effect maximizes product absorption and avoids excess residue on the skin surface. Spray-on fragrances also benefit from microspray technology, as the fine spray particles ensure even dispersion of the fragrance in the air, enhancing the user experience.

The Screw Microsprayer also has potential applications in food processing. For example, when applying protective films or spraying seasonings or sauces on food surfaces, microspraying ensures even coverage of each layer of liquid, enhancing the product's taste and appearance. By precisely controlling the amount of liquid, food processing quality can be significantly improved, ensuring both safety and aesthetic appeal.

With the increasing global emphasis on environmental protection and sustainable development, microspraying technology and the packaging industry are undergoing profound transformation. For companies like Yuyao Hongbang Packaging Co., Ltd., future development requires not only keeping pace with industry technological innovation but also focusing on product innovation and optimization within the context of environmental protection and intelligent manufacturing. Since its establishment in 2005, Yuyao Hongbang Packaging Co., Ltd. has been committed to providing innovative plastic packaging solutions, primarily covering flip-top closures, valve closures, two-color closures, lotion pumps, and other categories, serving a variety of industries, including personal care, beauty, cleaning, pharmaceuticals, and food. As industry trends evolve, how Yuyao Hongbang Packaging Co., Ltd. responds to these trends and maintains its competitive advantage is key to the company's future development.

In the future packaging industry, intelligence and automation will be key development directions, particularly in production efficiency, quality control, and customized services. Hongbang Packaging has laid a solid foundation in this area through a comprehensive production chain, encompassing product design, mold development, automated injection molding, and assembly. With the introduction of intelligent manufacturing and big data technologies, Hongbang Packaging can further improve production efficiency, achieve precise control over every production link, reduce manual intervention, lower production costs, and ensure that each packaged product meets consistent high-quality standards.

Intelligence also provides new opportunities for personalized packaging customization. Through intelligent systems, Hongbang Packaging can more flexibly respond to rapidly changing market demands and provide personalized and customized packaging solutions to meet the diverse needs of different customers. For example, in the cosmetics and pharmaceutical industries, customers are increasingly demanding packaging that is both functional and aesthetically pleasing. Intelligent production systems can quickly respond to these demands, providing more precise product design and efficient production capabilities.

With stricter environmental regulations and rising consumer awareness, the packaging industry is placing increasing demands on environmental protection and sustainable development. Against this backdrop, Yuyao Hongbang Packaging Co., Ltd. has actively promoted the use of environmentally friendly materials. For example, Hongbang Packaging has begun to increasingly utilize environmentally friendly materials such as PCR and TPE in its products. These materials not only reduce environmental impact but also offer the same high performance as traditional plastics.

As environmental trends deepen, Hongbang Packaging will place greater emphasis on improving the recyclability and biodegradability of its products and using low-carbon emission materials to comply with global environmental regulations and market demands. Incorporating eco-friendly packaging design, Hongbang Packaging will also continuously optimize resource efficiency and reduce waste emissions throughout its production process, achieving a green, low-carbon, and sustainable production model.

With increasingly stringent global environmental standards, companies must not only consider cost reduction but also assess the environmental impact of their products throughout their lifecycles. Hongbang Packaging's quality management system and innovative R&D team have provided technical support and guidance to achieve this goal. Going forward, Hongbang Packaging will promote the application of sustainable packaging in a wider range of areas, striving to become an industry leader in environmentally friendly packaging.

In addition to the trends toward smart and environmentally friendly packaging, competition in a globalized market is also driving companies to continuously expand their business scope and move toward internationalization. While providing high-quality packaging products to the domestic market, Hongbang Packaging is also actively developing international business to meet global demand for high-quality packaging. With growing demand for environmentally friendly and personalized packaging in the European and American markets, Hongbang Packaging is expected to further enhance its international competitiveness by expanding its overseas market share.

To meet this trend of internationalization, Hongbang Packaging will need to increase investment in cross-border collaboration and overseas market development, providing customers with global, standardized services through more flexible production and supply chain management. Furthermore, with growing global consumer demand for personalized and customized packaging, Hongbang Packaging can rapidly respond to market demand through flexible production lines and intelligent equipment, enabling personalized product customization to meet the diverse needs of different national and regional markets.

English

English 中文简体

中文简体 русский

русский Español

Español