For 20 years

We focused on one thing

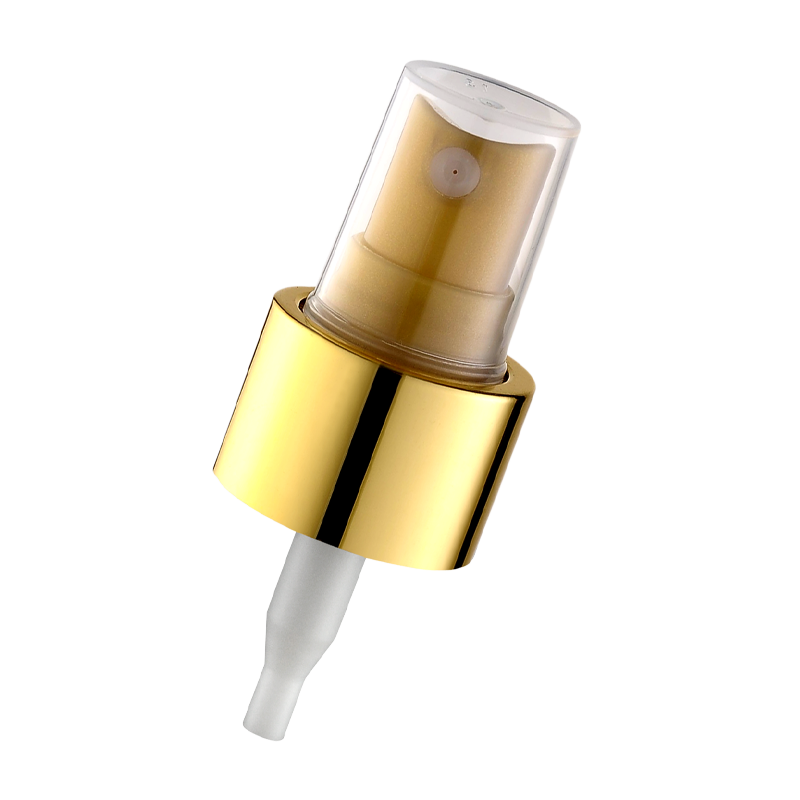

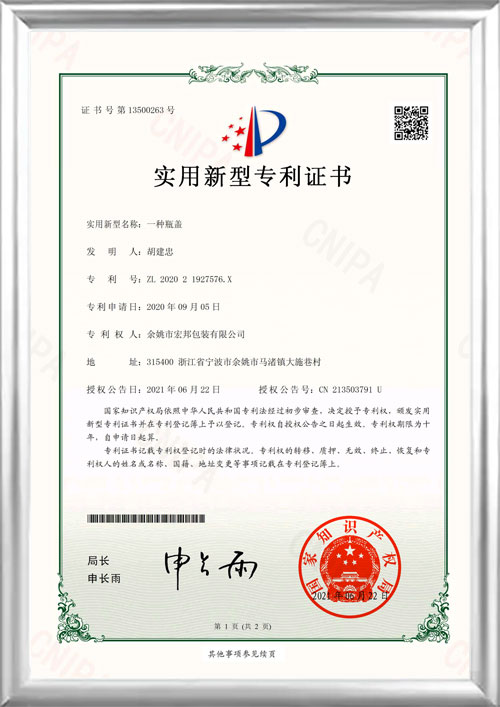

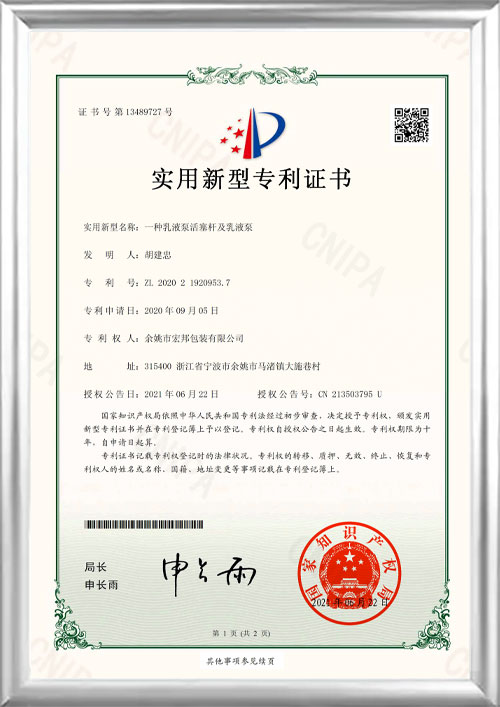

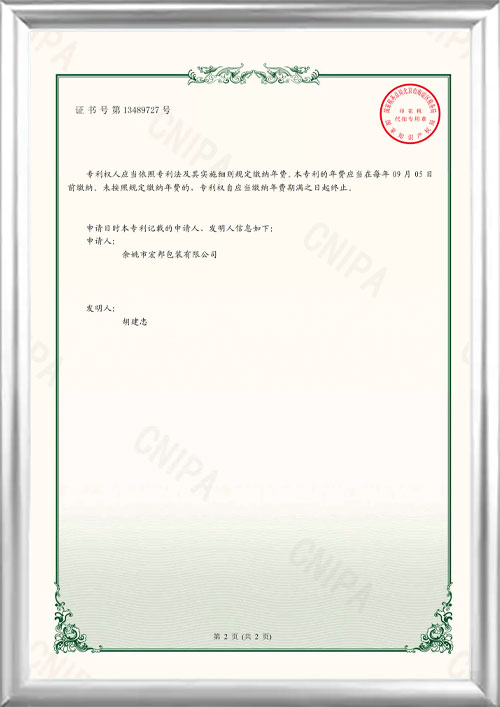

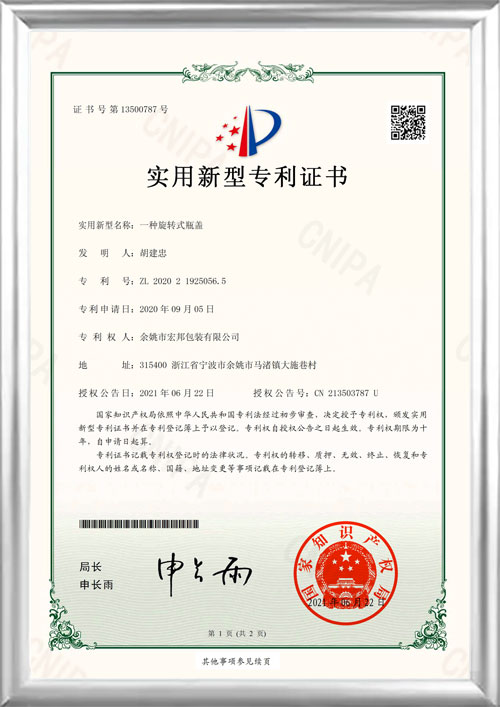

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Plastic Screw microsprayer 0.18ML/T Suppliers and OEM Screw microsprayer 0.18ML/T Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

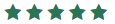

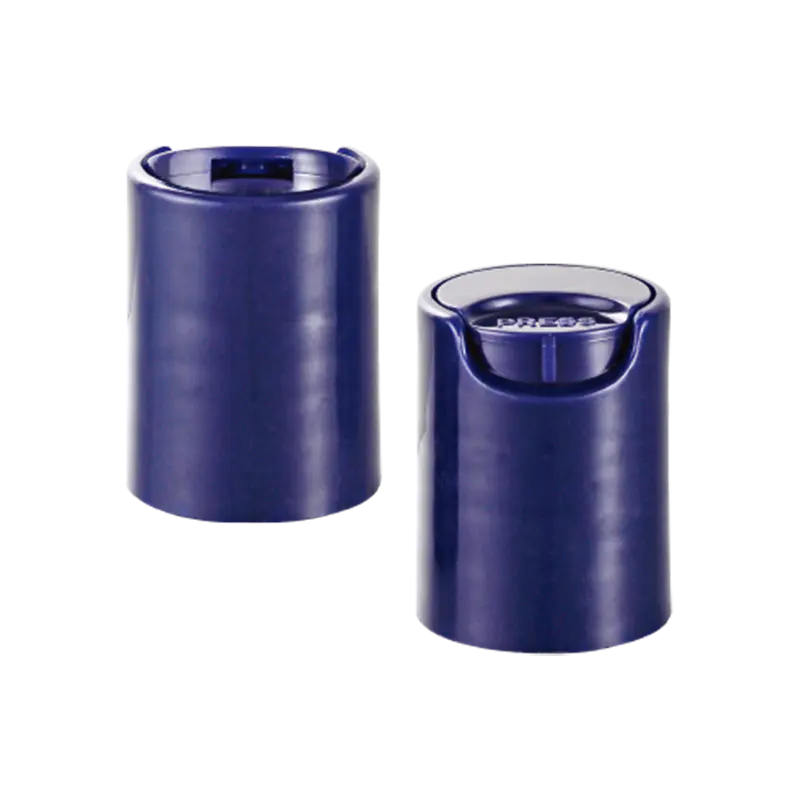

The Screw Microsprayer 0.18ml/T is a small sprayer specifically designed for efficient and precise liquid dispensing. It is typically used with a screw-on cap. Its most notable feature is its precise and even spray volume of 0.18ml per spray. This microsprayer is widely used in the cosmetics, personal care, pharmaceutical, and cleaning industries, particularly when small amounts of liquid need to be precisely dispensed.

This sprayer's design allows for a fine, mist-like spray of liquid. It is typically used for small-volume packaging, minimizing waste while ensuring a consistent and uniform dosage. Unlike traditional large-volume sprayers, the Screw Microsprayer 0.18ml/T offers greater precision, making it ideal for dispensing expensive or rare liquids such as serums, medications, or luxury perfumes.

The Screw Microsprayer 0.18ml/T operates similarly to a traditional sprayer, requiring the press of a trigger or button to force the liquid inside to the nozzle. However, its most significant feature is its controlled 0.18ml spray volume per spray, ensuring a compact and precise spray. Its design prioritizes uniform atomization of the liquid with every use and minimizes liquid waste during each spray.

Spiral Connection: The Screw Microsprayer utilizes a spiral connection that securely connects to the bottle neck. This spiral design ensures a secure connection between the sprayer and the bottle, preventing leaks and ensuring safe and reliable application.

Micro Nozzle: The sprayer's nozzle is extremely fine, atomizing the liquid into extremely small particles. This spray effect not only conserves liquid but also improves application uniformity. This is particularly important in the beauty and pharmaceutical industries, where precise control of the spray volume is crucial.

Precise Dosage Control: Each spray volume is 0.18 ml, making the Screw Microsprayer ideal for products requiring controlled dosage. Examples include skincare serums, perfumes, and eye drops. Excessive use can lead to waste or skin irritation, making precise dosage control crucial.

Sealed and Leak-Proof Design: Thanks to its screw cap and tightly sealed internal components, the Screw Microsprayer effectively prevents leakage during transport and storage. This makes it suitable for high-value, volatile, or contaminant-prone liquids, such as essential oils and pharmaceuticals.

The Screw Microsprayer 0.18 ml/t has a wide range of applications across multiple industries, including the following:

Cosmetics and personal care: This sector is one of the primary applications for the Screw Microsprayer. Many skincare products, serums, toners, and other products require precise control of dosage per application. The 0.18ml/t Screw Microsprayer perfectly meets this need, preventing overuse, improving product efficiency, and enhancing the user experience. For example, high-end skincare products like serums are often highly concentrated and expensive. Precise spray dosing allows consumers to better control how much they use and reduce waste.

Perfume and Fragrance Products: Perfume is another product typically used with the 0.18ml/t Screw Microsprayer. Perfume is typically used in smaller quantities, making spray uniformity and dosage control particularly important. The precise control of the Screw Microsprayer ensures a smooth and even application while reducing waste. For high-end perfumes, precise control of the amount used per application, preventing overspray, extends the perfume's lifespan, and enhances the consumer experience.

Pharmaceutical and Healthcare Products: In the pharmaceutical industry, precise spray dosing is crucial, especially for delicate medications such as nasal sprays and eye drops. The Screw Microsprayer 0.18ml/T in this application ensures precise, accurate application of medications every time, eliminating the health risks associated with inaccurate dosing. This precise control also provides consumers with greater safety and reliability.

Cleaning and Deodorization Products: Some cleaning products, air fresheners, and deodorizing sprays also utilize this micro-sprayer design, particularly when precise, small doses of liquid need to be dispensed. For example, air fresheners utilize micro-atomization to evenly cover a room, minimizing waste and improving effectiveness.

Food Packaging: Although less common, some spray products in the food industry, such as seasonings and oil sprays, also utilize micro-sprayers. For these food products, the Screw Microsprayer enables precise dosing, ensuring convenient and hygienic use.

With increasing consumer demand for high efficiency, environmental friendliness, and precise control, the market potential and application areas of the Screw Microsprayer 0.18ml/T continue to expand. Particularly in the cosmetics, pharmaceutical, and personal care industries, the precise dosage control and fine spray effects of micro-sprayers have become a key trend in product packaging. By continuously innovating and improving technology in line with this trend, screw microsprayers have gradually become a standard across many industries.

Environmental protection and sustainability are currently hot topics in the packaging industry, especially in the personal care and cosmetics sectors, where consumers have higher expectations for the environmental friendliness and recyclability of packaging materials. Since its establishment in 2005, Yuyao Hongbang Packaging Co., Ltd. has been committed to providing packaging solutions that meet modern environmental standards and continuously promoting the use of recyclable materials (such as PCR plastics) and biodegradable materials. By continuously optimizing product design and adopting green materials, Yuyao Hongbang Packaging Co., Ltd. has not only enhanced its product's market competitiveness but also met the global demand for eco-friendly packaging.

As a company specializing in packaging solutions, Yuyao Hongbang Packaging Co., Ltd.'s screw microsprayer products have also begun to utilize environmentally friendly materials extensively, ensuring efficient spraying while reducing environmental impact. This not only complies with increasingly stringent environmental regulations but also caters to the market trend towards sustainable development. In the future, as consumers' awareness of environmental protection continues to deepen, environmentally friendly screw microsprayers will become a mainstream choice in the market.

With the continuous advancement of technology, the functions of screw microsprayers are also constantly innovating and upgrading. For example, intelligent sprayers may gradually become a major trend in the industry. Utilizing sensor technology and intelligent control systems, future sprayers will not only automatically adjust the spray volume based on the liquid type and the remaining amount in the bottle, but also provide a personalized user experience. The emergence of intelligent microsprayers will go beyond basic spray functions and may also incorporate more adjustable parameters, such as spray intensity and spray volume, to meet the needs of different consumers.

Yuyao Hongbang Packaging Co., Ltd., leveraging its strong R&D capabilities and sophisticated manufacturing technology, is committed to promoting technological upgrades in the sprayer industry. The company's strengths in precision mold design and manufacturing enable it to quickly respond to market demands and provide microsprayer molds with higher precision and longer lifespans. All of this will accelerate the development of intelligent and high-performance screw microsprayers. By leveraging precision molds and advanced automated injection molding technology, Hongbang Packaging can effectively reduce production cycle times while ensuring the high quality standards of each sprayer product.

With increasing consumer demand for personalization and customization, future Screw Microsprayers may feature more features, such as adjustable spray volume, variable spray patterns, and anti-clogging features. This multifunctional design not only meets the needs of diverse applications but also allows each user to enjoy a more personalized product experience.

Against this backdrop, Yuyao Hongbang Packaging Co., Ltd., leveraging its strong product development and mold design capabilities, is able to quickly respond to market demands and provide customized solutions. Hongbang Packaging's advanced technology not only enables efficient and high-precision production, but also enables the design of unique, multifunctional sprayers tailored to customer needs, providing the market with a wider range of options.

Yuyao Hongbang Packaging Co., Ltd.'s success lies not only in its sophisticated technology and product innovation, but also in its efficient industrial chain integration. The company boasts an annual production capacity of over 200 sets of mid- to high-end precision molds and produces over 200 million plastic products annually. This production capacity enables Hongbang Packaging to rapidly respond to customer needs and provide high-quality and efficient production solutions.

Yuyao Hongbang Packaging Co., Ltd. is committed to providing customers with comprehensive services, from product development, mold design, mold manufacturing, injection molding, to assembly production, ensuring efficient execution of every step from design to manufacturing. This one-stop service model not only improves production efficiency but also reduces production costs, enabling the company to provide customers with high-quality micro-sprayers at more competitive prices.

With the increasing global production demand, Yuyao Hongbang Packaging Co., Ltd.'s comprehensive service offering has undoubtedly become a key strength of its market competitiveness. Through the optimization and integration of its industrial chain, Yuyao Hongbang Packaging Co., Ltd. has improved product quality while ensuring it can meet the growing needs of customers worldwide.

English

English 中文简体

中文简体 русский

русский Español

Español