For 20 years

We focused on one thing

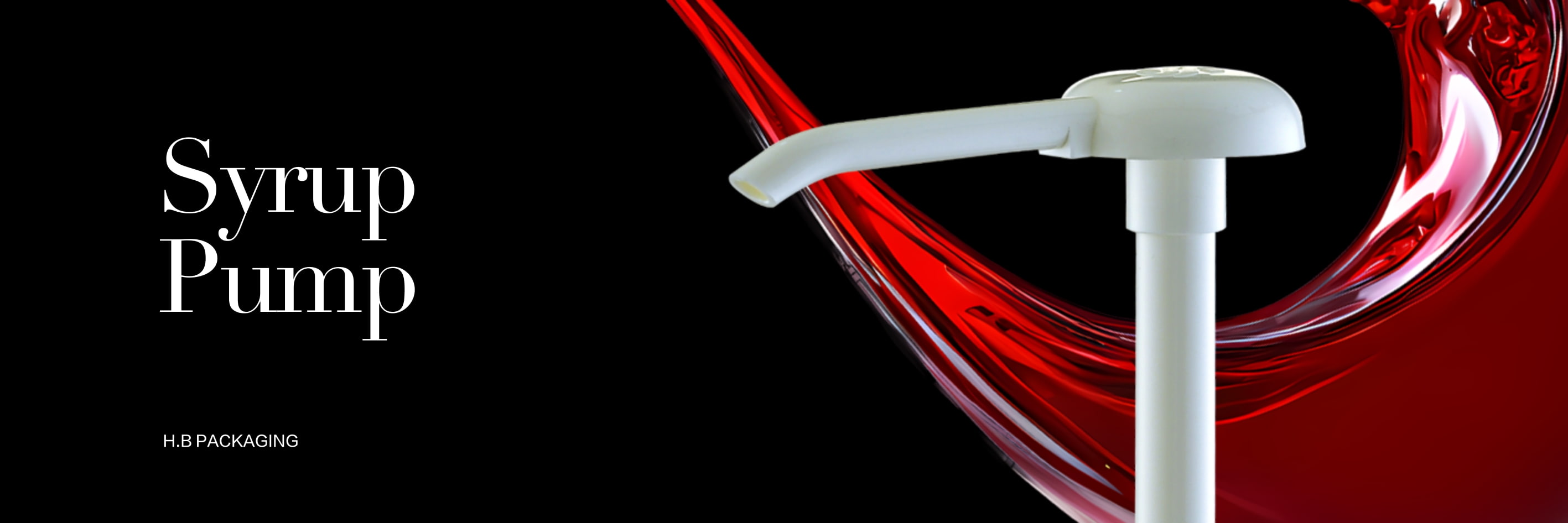

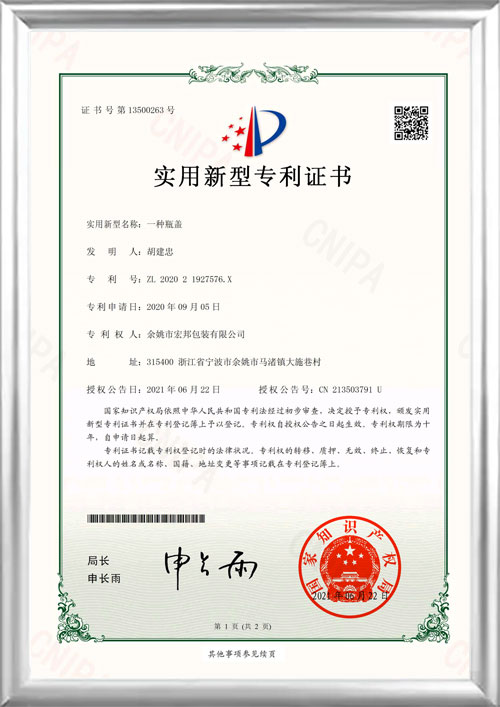

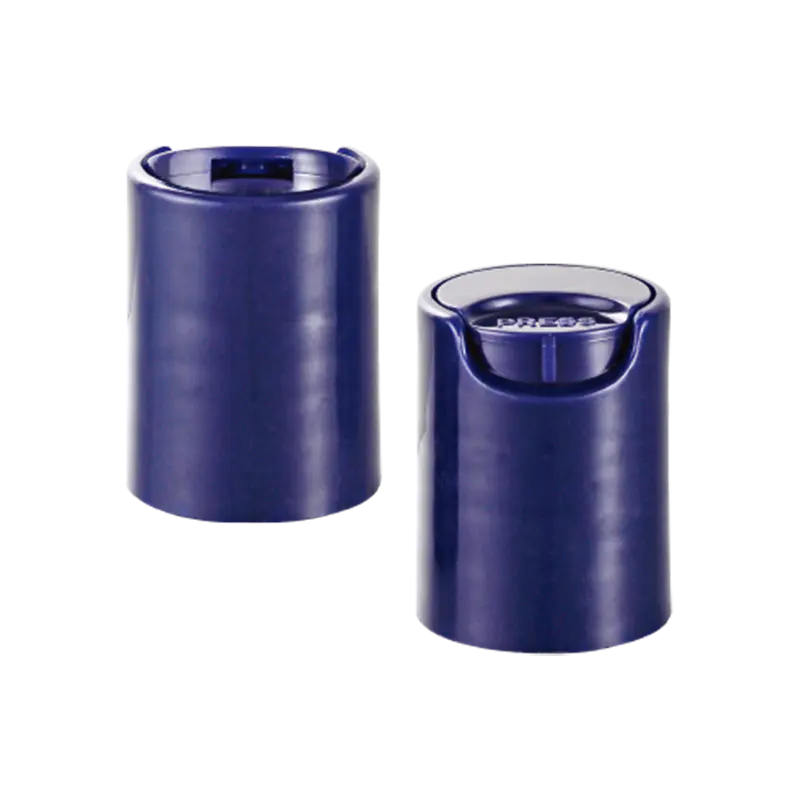

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Syrup Pump/ Syrup Dispenser 30ML/T Suppliers and OEM Plastic Syrup Pump/ Syrup Dispenser 30ML/T Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

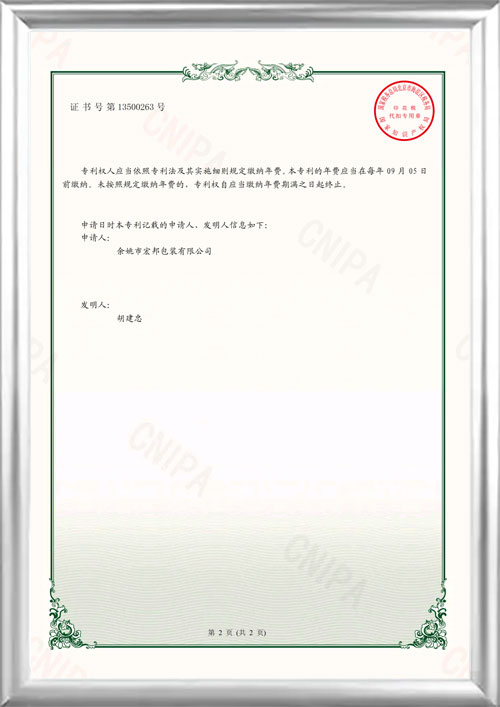

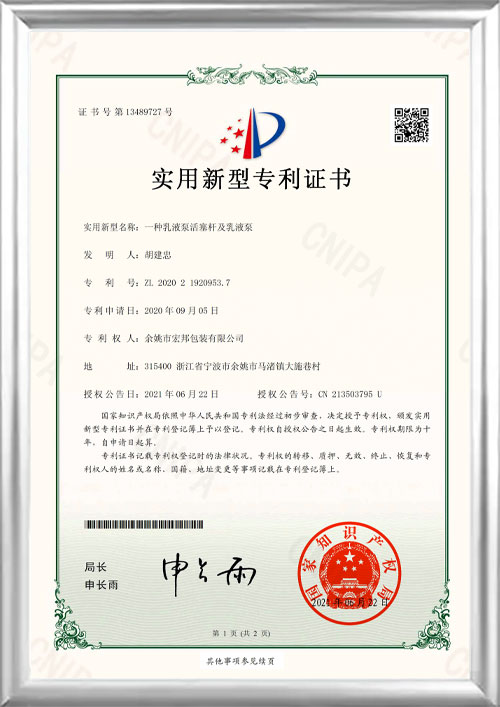

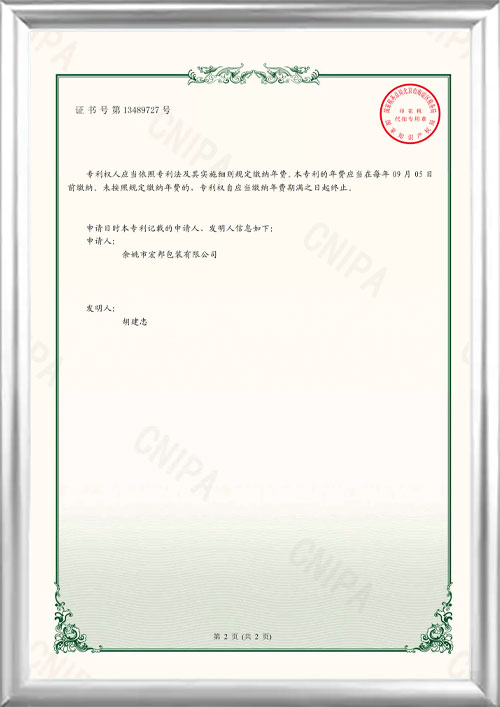

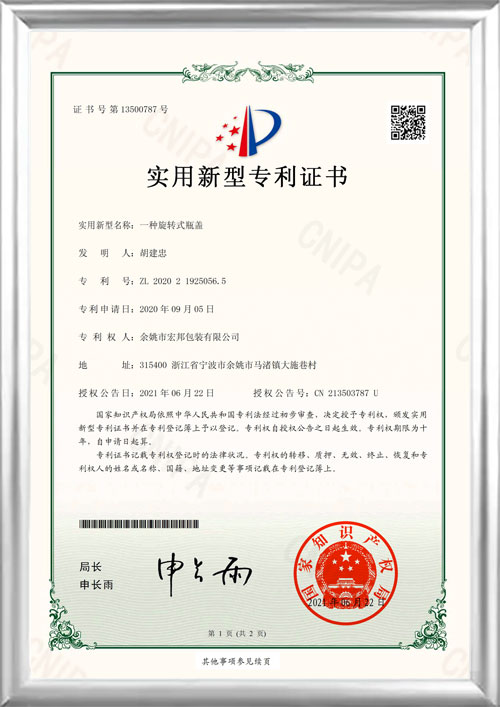

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

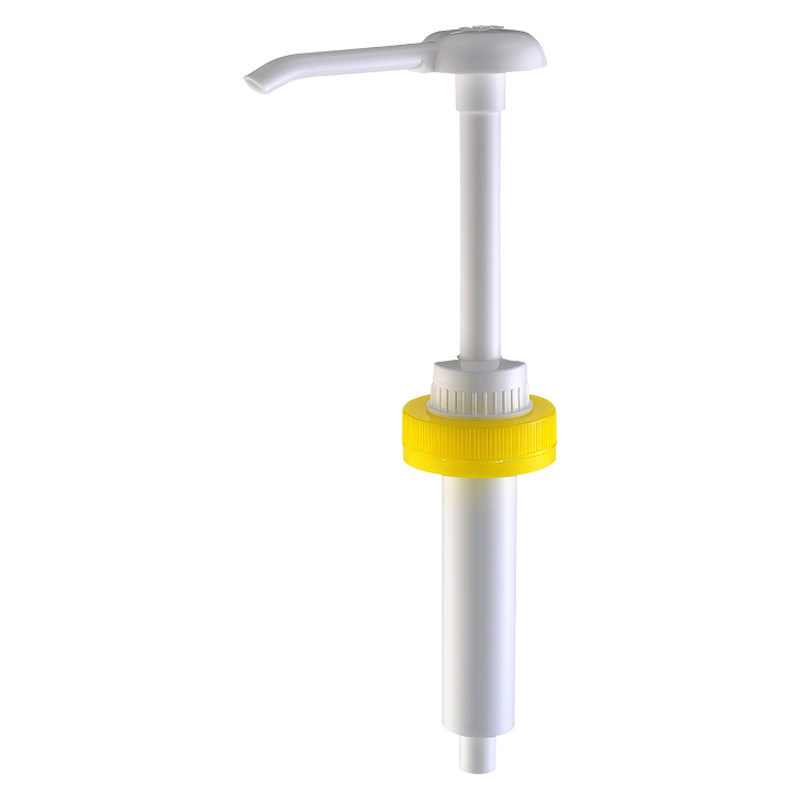

The Syrup Pump/Syrup Dispenser 30ML/T is a dispensing device designed specifically for liquid syrup products. It accurately and conveniently dispenses syrup from bottles, eliminating the waste and inaccuracies associated with traditional pouring methods. Syrup pumps are commonly used in restaurants, cafes, hotels, beverage shops, and other establishments. They significantly improve operational efficiency and ensure accurate dispensing when serving beverages (such as coffee, milk tea, and juice), desserts (such as pancakes and ice cream), and syrup products.

The 30ML/T capacity of this device means that each press of the pump evenly dispenses 30ml of syrup. This precise dispensing mechanism makes syrup use more efficient and avoids waste caused by overdosing. Precise syrup dispensing significantly improves work efficiency, especially in high-volume commercial settings.

The core function of a syrup pump is to ensure consistent and accurate syrup dispensing every time. The 30ml/T dispensing volume perfectly meets the syrup requirements of many businesses when preparing drinks or desserts. For example, cafes often require precise control of syrup dosage when preparing different flavors. The syrup pump's design ensures that, whether it's vanilla, caramel, or chocolate syrup, each pump dispenses an exact 30ml, eliminating the inaccuracies associated with traditional manual pouring.

This precise dispensing design not only improves service efficiency but also helps businesses better control syrup usage, reducing waste and improving cost-effectiveness. Especially in busy food and beverage environments, precise syrup dispensing speeds up workflow and ensures customers receive standardized, consistent drinks.

Syrup pumps are often designed for convenience and easy cleanability. The simple and efficient pump head design allows for quick operation and easy disassembly for cleaning, eliminating the stickiness associated with traditional syrup bottles. Especially in high-frequency commercial use scenarios, cleaning and maintenance of syrup pumps are particularly important. Easy-to-clean pump heads and tubing can reduce hygiene risks and ensure the syrup remains hygienic and fresh.

Customer experience is crucial in the food and beverage industry. Using a syrup pump ensures a consistent taste experience with every purchase, ensuring a uniform syrup concentration and consistent taste in every cup. This is crucial for brand image building, enhancing brand consistency and customer loyalty.

Compared to open containers, syrup pumps maintain syrup hygiene more effectively. The sealed design between the pump head and the container effectively reduces contact with air and bacteria, preventing syrup from contamination and spoilage. This hygienic performance is particularly important in locations where syrup is used for extended periods of time, such as large-scale restaurants and chain stores, helping to reduce hygiene issues and improve product quality.

1. Food and Beverage Industry: Syrup pumps are widely used in the food and beverage industry, particularly in establishments serving beverages such as coffee, milk tea, juice, and ice cream. Cafés often use syrup pumps to control the amount of syrup dispensed, ensuring a consistent amount of syrup in every cup of coffee, latte, mocha, and other drinks, thus providing a standardized taste. Whether it's caramel syrup, vanilla syrup, or chocolate syrup, a syrup pump ensures the precise flavor of each drink.

2. Beverage Manufacturers: Large beverage manufacturers also use syrup pumps to package and dispense syrups, especially in large-scale production, ensuring a consistent syrup ratio in every bottle. This is crucial for production efficiency and quality control. Syrup pumps also help manufacturers reduce waste during the bottling process, improve raw material utilization, and thus lower production costs.

3. Desserts and Ice Cream Shops: When preparing desserts like ice cream, pancakes, and waffles, syrup pumps precisely dispense syrup, eliminating the inconsistent amounts of syrup that can occur with manual labor. This ensures that each dessert achieves the desired taste and appearance, enhancing the customer experience.

4. Hotels and Buffets: Hotels and Buffets often offer a variety of syrups as condiments. Syrup pumps allow customers to dispense syrups themselves, preventing waste. When serving a variety of desserts and drinks, buffets can use syrup pumps to provide more precise syrup dispensing, ensuring every customer's needs are met while also preventing overuse.

5. Food Processing and Packaging: Syrup pumps are also used in food processing companies for syrup packaging and dispensing. In large-scale syrup production, syrup pumps help companies efficiently and safely dispense and package syrup, while ensuring the precise amounts dispensed meet product recipe requirements.

With evolving consumer demands and growing environmental awareness, the syrup pump industry is experiencing rapid growth. In particular, the global catering, food, and personal care industries are increasingly demanding higher standards for product packaging precision and environmental friendliness, presenting new opportunities and challenges in the syrup pump market.

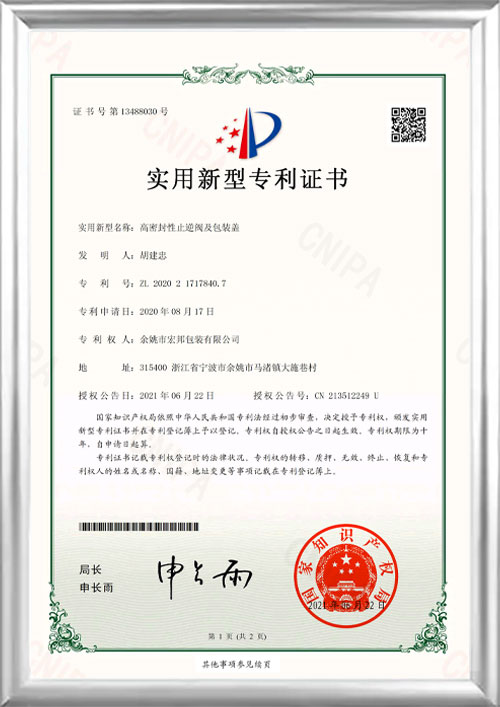

With increasingly stringent environmental regulations, the plastic packaging industry is facing tremendous pressure. In particular, the use of biodegradable materials and the reduction of plastic waste have become key areas of business development. Yuyao Hongbang Packaging Co., Ltd. understands the importance of this trend and is committed to providing customers with environmentally friendly packaging solutions. In product design and production, especially in the development of syrup pumps, the company has actively adopted recyclable and polymerized materials to promote green packaging. By increasing the use of environmentally friendly materials, Hongbang Packaging not only complies with domestic and international environmental policies, but also helps customers reduce plastic pollution and enhance their brand's environmental image.

Yuyao Hongbang Packaging Co., Ltd. also continuously optimizes its production processes, minimizing resource waste through precise mold design and efficient production processes. For example, the company's adoption of multi-cavity mold technology not only improves production efficiency but also reduces the unit cost of each syrup pump, making the environmentally friendly material more competitive in price.

The application of intelligent technology in the packaging industry continues to expand, and the future development trend of syrup pumps will be intelligent and automated. With growing demand from the catering and retail industries, syrup pumps must not only meet basic precise dispensing functions but also possess greater flexibility and adaptability. For example, by integrating smart sensors or connecting to POS systems, syrup pumps can enable remote control, data analysis, and real-time monitoring, thereby improving operational efficiency, reducing errors, and optimizing syrup dispensing quantities.

With intensifying market competition, personalized and customized products are becoming increasingly important to consumers and businesses. The design and functional settings of syrup pumps will gradually move towards personalized customization, especially in the catering industry. Packaging design requirements are no longer limited to functionality; enhancing brand image and consumer experience are also becoming increasingly important.

Yuyao Hongbang Packaging Co., Ltd., with its strong R&D capabilities and sophisticated multi-cavity mold design technology, can provide customized solutions based on customer needs. For example, the color, shape, and pump head flow rate of syrup pumps can all be customized to suit different brands' positioning and market needs, ensuring product uniqueness and brand consistency. Yuyao Hongbang Packaging Co., Ltd.'s customization services extend beyond design to include adjustments to the pump head's precision and flow rate based on different syrup types (e.g., viscous or liquid syrups), ensuring consistent syrup flow every time, enhancing customer satisfaction.

As a high-precision packaging product, the production process for syrup pumps places extremely high demands on technology and equipment. Against this backdrop, Yuyao Hongbang Packaging Co., Ltd., leveraging its robust production capabilities and precision mold technology, can efficiently meet customers' large-scale production needs for syrup pumps. The company boasts an annual production capacity of over 200 sets of mid- to high-end precision molds and can produce over 200 million plastic products annually, enabling it to meet the high-volume demands of clients across various industries.

By optimizing production processes, Yuyao Hongbang Packaging Co., Ltd. continuously improves production efficiency, shortens production cycles, and ensures high product quality and precision even at high volumes. This gives Yuyao Hongbang Packaging Co., Ltd. an edge in the fiercely competitive market, providing reliable syrup pump solutions for a variety of industries, including catering, food, medical, and cosmetics.

Yuyao Hongbang Packaging Co., Ltd.'s comprehensive production chain encompasses a full-process service from product design and mold development to injection molding and assembly, ensuring precision and efficiency. Whether it's a standardized syrup pump or a customized design, Yuyao Hongbang Packaging Co., Ltd. offers a comprehensive, one-stop solution, helping customers complete the entire process from product design to final production in a short period of time.

Innovation is the driving force behind a company's sustainable development. Yuyao Hongbang Packaging Co., Ltd. is committed to enhancing the technical level and market competitiveness of its products through R&D and innovation. The company has a professional R&D team focused on product innovation, technological advancement, and the application of new materials, striving to provide customers with more advanced syrup pump solutions that meet market needs.

For example, Yuyao Hongbang Packaging Co., Ltd. continuously researches and applies new environmentally friendly materials, such as TPE (thermoplastic elastomer) and PCR (post-consumer recycled plastic), to ensure the durability and functionality of pump heads while minimizing environmental impact. The company also continuously innovates in intelligent design and precision mold technology, driving performance optimization for syrup pumps and the launch of new products.

English

English 中文简体

中文简体 русский

русский Español

Español