For 20 years

We focused on one thing

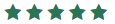

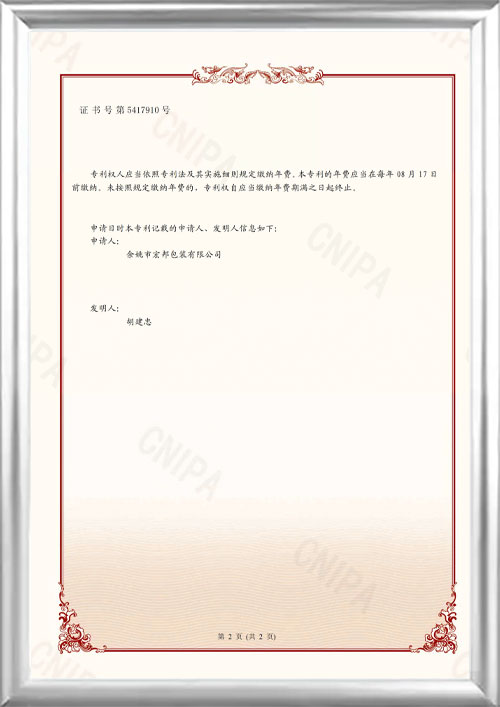

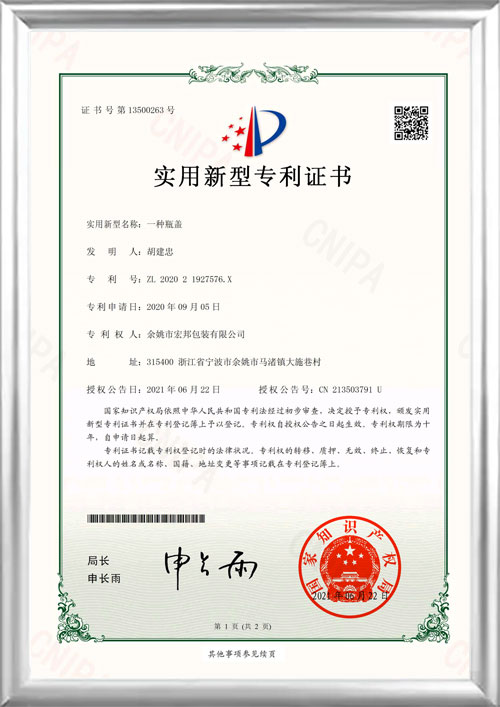

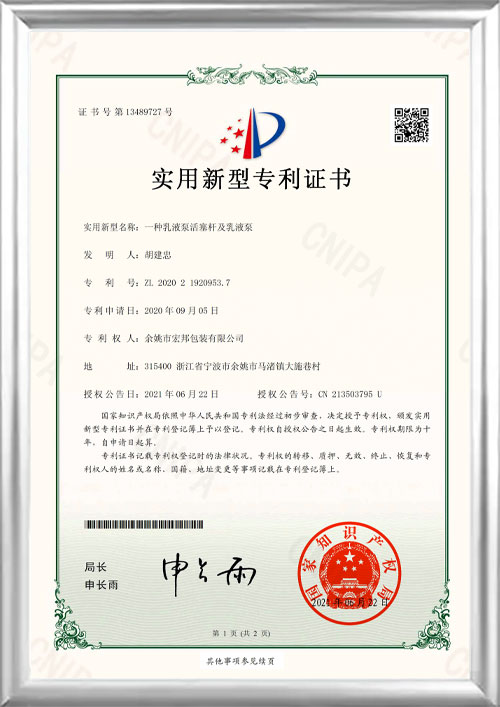

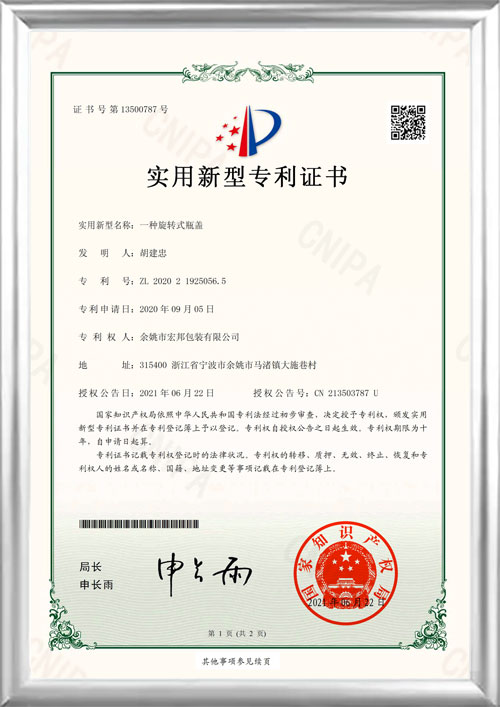

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Left-right Lock Lotion Pump 2.0ML/T Suppliers and OEM Plastic Left-right Lock Lotion Pump 2.0ML/T Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

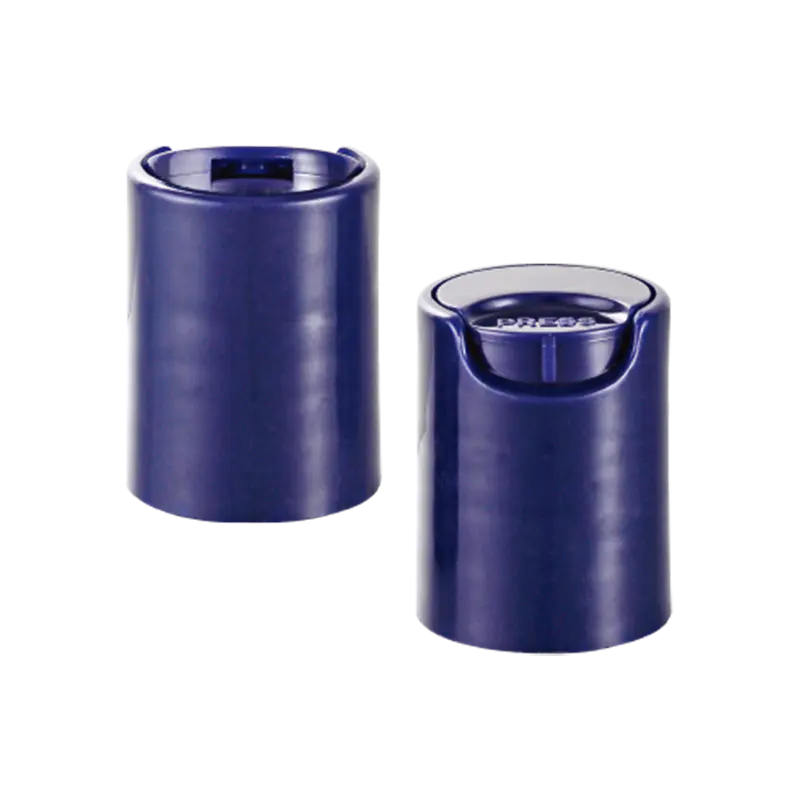

One of the design advantages of the Plastic Left-Right Lock Lotion Pump 2.0ML/T is its left-right locking mechanism, which not only provides enhanced pump head security but also improves ease of use. Specifically, this design allows the pump head to be locked and unlocked with a simple left-right twist, preventing accidental leaks during transport, storage, or daily use. The popularity and application of this locking mechanism stems from the dual demand for safety and convenience in liquid dispensing devices in the market.

The primary function of the left-right locking design is to prevent the pump head from leaking when not in use. During transport, many liquid products (such as skincare and cosmetics) can leak due to pressure fluctuations or vibration if not locked properly. This not only wastes resources but also compromises the product's appearance and quality. By rotating the pump head to the "locked" position, the liquid is secured and prevented from leaking. For consumers, this design not only protects product integrity but also provides a better user experience.

Left-right locking pumps are commonly used in the packaging of liquid or lotion products, such as daily skincare, shampoo, and body wash. These products often need to prevent leakage when not in use, making a locking feature of the pump head particularly crucial during long-term storage or transportation. Pump heads with locking features are also popular in baby care products and medical supplies. The locking design effectively prevents the risk of accidental operation by children or spillage, further enhancing product safety.

With evolving market demands and increasing consumer demand for high-quality products, traditional pump head designs are no longer able to meet these increasingly diverse needs. Many companies are adopting more user-friendly locking designs, including adjustable locking force and more sophisticated locking mechanisms. These innovations not only improve locking precision, but also enhance user convenience and product safety.

With tightening environmental regulations, designers face the challenge of ensuring locking functionality while employing more environmentally friendly and recyclable materials. Plastic materials must comply with new environmental requirements, requiring pump head manufacturers to innovate in materials and production processes while ensuring product functionality.

The amount of liquid dispensed with each pump stroke is typically determined by the design of the pump head and the spring system. For a plastic left-right lock pump, a 2.0ml/T capacity means each pump delivers a uniform 2.0ml of liquid or lotion. This precise dispensing mechanism is particularly useful for consumers who demand precise dosages. For example, high-end skincare brands often design their products based on precise dosage amounts to ensure optimal skincare results. Furthermore, precise volume control can help consumers reduce waste and improve product efficiency.

Precise pump volume control not only allows consumers to better control the amount of product used each time, preventing overuse and waste, but also demonstrates a sense of responsibility towards the brand. Many cosmetics and skincare brands use expensive ingredients, so every drop of liquid is precious. Precise pump head control ensures a consistent amount of liquid with each pump, enhancing the user experience. Whether it's everyday skincare or professional skincare, precise dispensing allows consumers to get the most out of every bottle, thereby increasing customer satisfaction and brand loyalty.

Precise pump head design can also help companies save on raw material costs. For manufacturers, precise dispensing means product dosage can be strictly controlled, reducing raw material waste, avoiding over-provisioning or redundant packaging, and further reducing production costs.

With increasing demand for personalization and customization, precise liquid dispensing technology has become a market trend. Many consumers expect to receive the exact amount of liquid dispensed according to their skincare needs. Manufacturers are also exploring ways to achieve this through more advanced technologies, such as variable spring force or more sensitive valve designs.

In the future, more innovative pump head designs may combine volume control with intelligent technology. For example, some premium skincare brands may launch pump heads with automatic dispensers that intelligently adjust the amount of liquid dispensed based on the user's skin type or frequency of use, further enhancing the personalized consumer experience.

Since its establishment in 2005, Yuyao Hongbang Packaging Co., Ltd. has specialized in producing a wide range of plastic packaging solutions, including pump heads, flip-top caps, valve caps, and two-color caps. Polypropylene and polyethylene are the primary materials of choice for plastic left-right lock pumps. These materials offer excellent chemical and corrosion resistance, making them ideal for packaging liquid products such as skincare, cosmetics, and household cleaning products. Through years of technical expertise and experience, Yuyao Hongbang Packaging Co., Ltd. is able to customize the pump head material and structure based on the specific characteristics of each product, ensuring stability and long-term service life.

Yuyao Hongbang Packaging Co., Ltd. prioritizes product quality and reliability, striving to provide highly durable plastic pump heads. As liquid dispensing devices, pump heads must possess strong pressure and wear resistance to withstand repeated use. During the production process, Hongbang utilizes its automated injection molding technology to ensure the precision and durability of each pump head component. Whether it's skincare lotion or shampoo, pumps are frequently used. Therefore, their material selection and design must prioritize durability and corrosion resistance to prevent loss of function or damage after prolonged use.

Transparent design not only allows consumers to clearly see the remaining amount of product but is also a key feature of Yuyao Hongbang Packaging Co., Ltd.'s products. The transparent pump design provides a high degree of visual clarity, allowing consumers to monitor remaining levels at all times, preventing unintentional use and enhancing convenience. In high-end skincare, cosmetics, and household cleaning products, transparent packaging often aligns with the product's high-quality image, increasing consumer trust and purchasing desire.

For example, many consumers prefer packaging designs that allow for a clear view of remaining volume because it provides a greater sense of control. As a company that offers customized services, Hongbang can customize transparent or translucent pump designs to suit the packaging needs of different brands. This design not only enhances the product's aesthetics but also improves the consumer experience, helping brands stand out in the market.

With growing global environmental awareness, the plastic packaging industry faces increasingly stringent environmental regulations. As an innovative company, Yuyao Hongbang Packaging Co., Ltd. is committed to promoting sustainable development and increasing the use of environmentally friendly materials, such as PCR and TPE, to reduce plastic pollution and minimize resource waste. PCR effectively reduces the demand for virgin plastic, while TPE offers improved recyclability, further enhancing the environmental value of the product.

Using environmentally friendly materials in the production of plastic pump heads not only reduces environmental impact but also complies with increasingly stringent regulations. Yuyao Hongbang Packaging Co., Ltd. is aligned with this trend, continuously improving its production processes through R&D and innovation to ensure that it not only meets functional requirements but also produces more environmentally friendly and safe products. Furthermore, the company continuously optimizes every aspect of the production process, including mold development, automated injection molding, and assembly, to further improve production efficiency and minimize environmental impact.

Yuyao Hongbang Packaging Co., Ltd.'s quality management system ensures that every pump head meets international standards. The company boasts an experienced R&D team capable of designing and customizing products based on individual customer needs, meeting market demand for innovation and high quality. In addition to product quality, sustainable development is also one of the important goals of Yuyao Hongbang Packaging Co., Ltd. By using environmentally friendly materials, optimizing production processes, and strengthening communication with customers, Yuyao Hongbang Packaging Co., Ltd. has established a responsible brand image in the plastic pump head industry.

English

English 中文简体

中文简体 русский

русский Español

Español