For 20 years

We focused on one thing

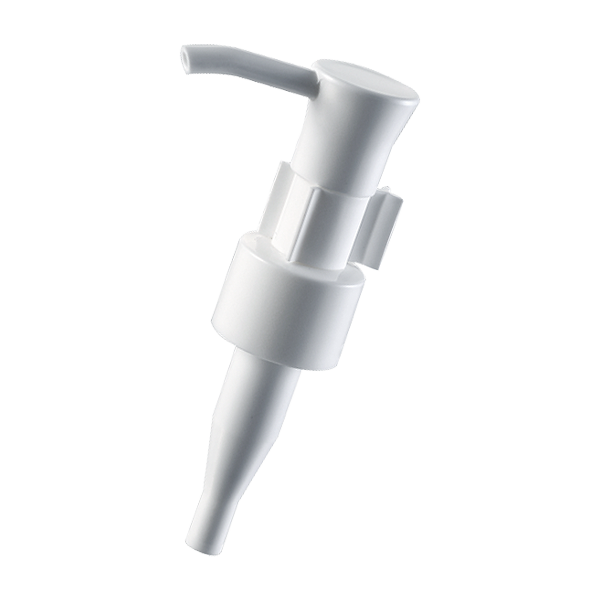

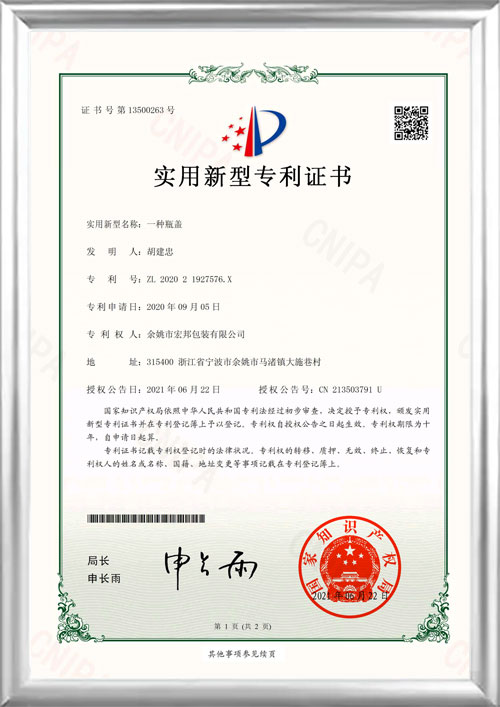

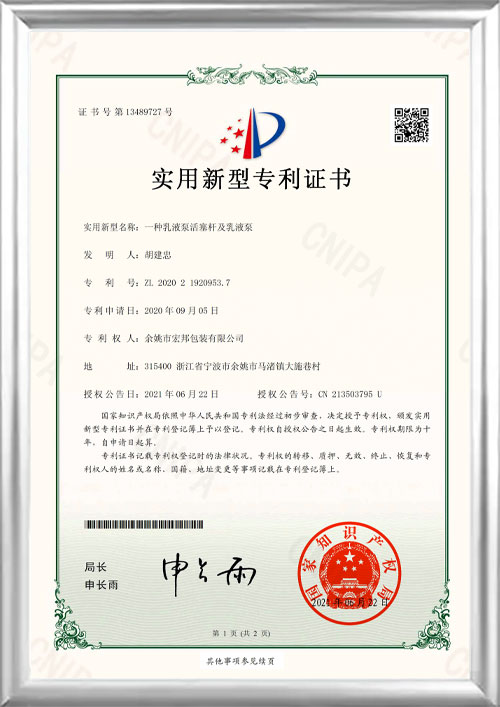

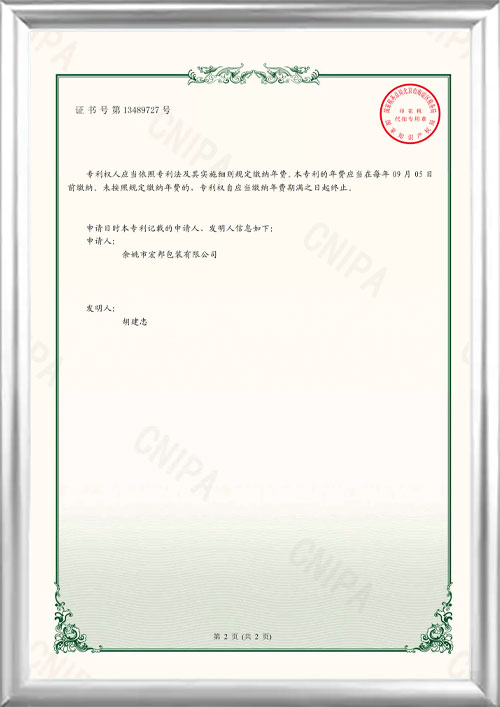

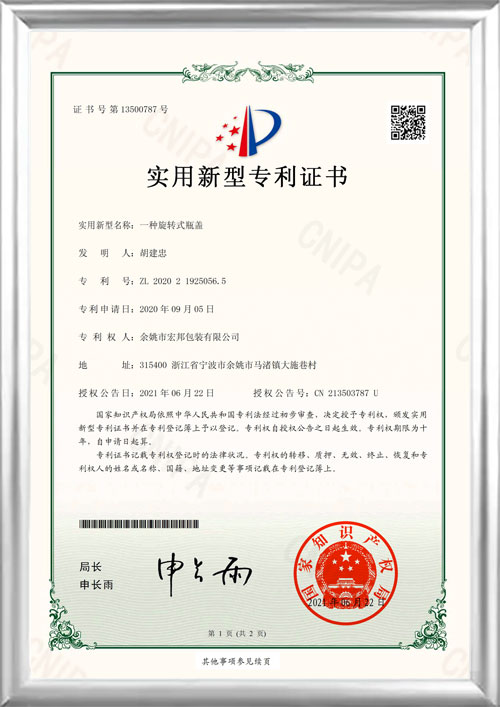

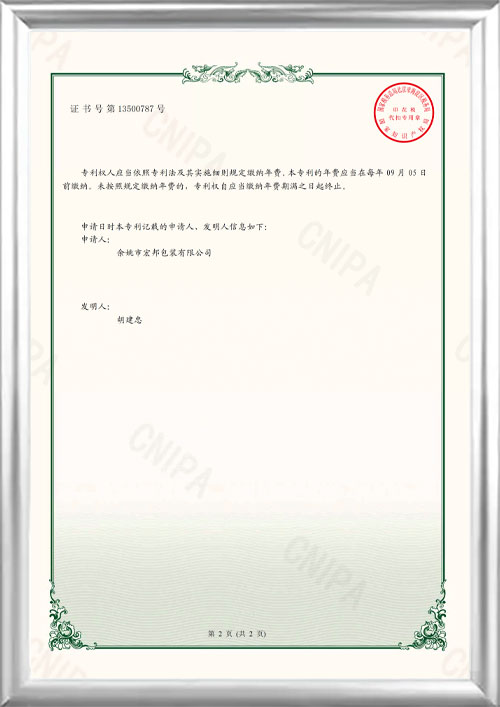

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Clip Lock Lotion Pump Manufacturers and Plastic Clip Lock Lotion Pump Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

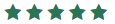

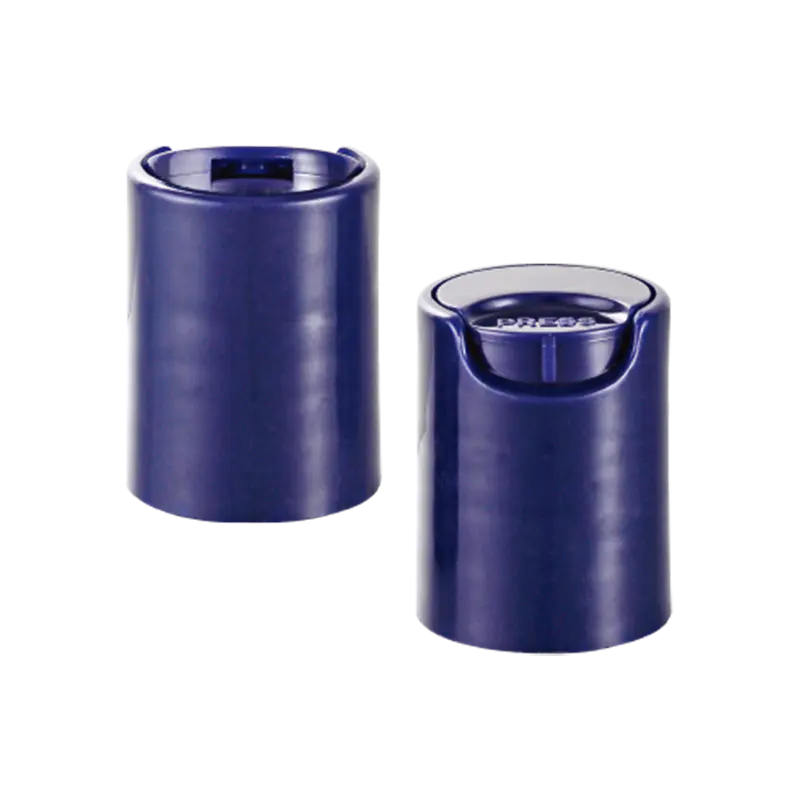

The Clip Lotion Pump 1ML/T is a precision dispensing tool widely used in the packaging of skincare products, cosmetics, pharmaceuticals, and cleaning products. Its structure consists of a pump head, pump tubing, and spring, and its overall design ensures ease of use, hygiene, and efficiency. The pump head's core components include a push button, a liquid channel, a spring, and a sealing ring. When the user presses the pump head, an internal piston is pushed, pushing liquid through the channel and out of the bottle opening. The unique feature of the Clip Lotion Pump 1ML/T is its precise dispensing capability. Each press accurately dispenses 1 ml of liquid, ensuring a consistent dose each time, thus avoiding waste. This is particularly important for liquid products that require precise dosage control, such as skin lotions, serums, and topical pharmaceuticals.

The Clip pump head design is another highlight. Its unique clamping mechanism secures the pump head to the bottle opening, preventing leakage during transport and storage. This design is particularly useful for volatile liquids or those requiring special storage requirements. It ensures the integrity of the liquid within a sealed environment, preventing contamination from air and external factors. The spring structure of the pump head ensures a smoother pumping action, ensuring quick and even dispensing of the liquid. The high-quality spring design also prevents the pump head from becoming stuck or unable to recover over time, thereby enhancing product durability and reliability.

The Clip Lotion Pump 1ML/T is widely used in various industries, particularly in skincare, cosmetics, pharmaceuticals, and cleaning products. Precise dispensing is crucial in the skincare and beauty industries. Consumers typically expect a fixed dose of skincare products each time they use them, avoiding wasting precious product by overdosing. The Clip Lotion Pump 1ML/T's precise dispensing effectively addresses this need, ensuring that each pump dispenses a controlled 1ml of liquid, improving product efficiency and helping to reduce costs for consumers.

In the cosmetics industry, particularly high-end skincare and serums, products are often priced high, leading consumers to demand precise control over the amount used to avoid waste. The Clip Lotion Pump 1ML/T not only provides this precise dosing control but also prevents product waste due to overuse, which is particularly important for modern consumers who prioritize environmental sustainability and sustainable consumption.

The pharmaceutical industry places even higher demands on pump accuracy and reliability, particularly in the packaging of topical medications and disinfectants. The Clip Lotion Pump 1ML/T ensures that each dispensed dose matches the recommended dosage in the instructions, which is crucial for patient health management. Whether it's a disinfectant or topical ointment, precise dosing enhances product effectiveness and prevents the negative effects of misuse or overdose.

This type of pump is also commonly used in the cleaning product industry, particularly for shampoo, shower gel, and hand soap. Its precise dispensing function helps users avoid waste while making it easier to control usage, thereby enhancing the consumer experience.

The Clip Lotion Pump 1ML/T is typically made of plastics such as polypropylene (PP) or polyethylene (PE). These materials offer excellent corrosion resistance and durability, while also being relatively cost-effective, making them suitable for large-scale production. However, for high-end markets or pharmaceutical packaging requiring long-term use, some pump heads utilize more durable materials such as stainless steel or aluminum alloy. While these materials are more expensive, they offer greater reliability and corrosion resistance, making them suitable for applications requiring the highest quality packaging.

With growing global environmental awareness, consumers have higher expectations for sustainable and environmentally friendly product packaging. Against this backdrop, Yuyao Hongbang Packaging Co., Ltd. is committed to providing the market with environmentally friendly packaging solutions through advanced technology and innovative design. As a professional packaging company established in 2005, Yuyao Hongbang Packaging Co., Ltd. has continuously improved its manufacturing processes through years of experience and exploration, offering customers a variety of efficient, environmentally friendly, and intelligent packaging products.

Precision dispensing technology is one of the highlights of the company's packaging solutions. The 1ML/T Clip Lotion Pump, part of the company's product line, features exceptionally high precision, dispensing 1ml of liquid at a time. This feature not only effectively reduces product waste but also helps consumers use every drop of liquid more efficiently. It is particularly suitable for products such as high-end skincare, pharmaceuticals, and precision ointments. This precise dispensing capability is particularly important in today's environmentally friendly trends that emphasize resource conservation and waste reduction, effectively reducing environmental impact and enhancing a brand's sense of social responsibility.

Yuyao Hongbang Packaging Co., Ltd. also prioritizes the use of recyclable and environmentally friendly materials in its packaging design. With increasingly stringent environmental regulations, market demand for green products is growing. The company utilizes recyclable materials such as polypropylene (PP) and polyethylene (PE) in its production. These materials not only meet environmental requirements but can also be recycled at the end of the product's lifecycle. Furthermore, with advances in biodegradable technology, the company is actively researching the use of bio-based plastics and other environmentally friendly materials, striving to provide customers with more sustainable packaging solutions.

In terms of technological innovation, Yuyao Hongbang Packaging Co., Ltd. leverages years of technical accumulation and research and development to provide multi-cavity precision molds and short-cycle production solutions. These innovative production processes not only improve production efficiency but also extend mold life, making the production process more stable and efficient. With an annual production capacity of over 200 sets of mid- to high-end precision molds, the company is able to quickly respond to market demand and meet diverse packaging design and functional requirements, particularly excelling in complex packaging solutions and personalized customization. Through these technological innovations, Yuyao Hongbang Packaging Co., Ltd. can provide customers with more flexible and environmentally friendly packaging products, further promoting the company's sustainable development.

With the advancement of intelligent and digital technologies, Yuyao Hongbang Packaging Co., Ltd. may also incorporate smart metering systems into its pump head designs in the future to further enhance precise dispensing capabilities. With built-in sensors and intelligent controls, consumers can customize the dispensing volume according to their needs, achieving a more personalized user experience. Furthermore, intelligent technologies can optimize production processes through data collection and analysis, reduce resource waste, and provide customers with more efficient packaging solutions.

English

English 中文简体

中文简体 русский

русский Español

Español