For 20 years

We focused on one thing

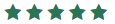

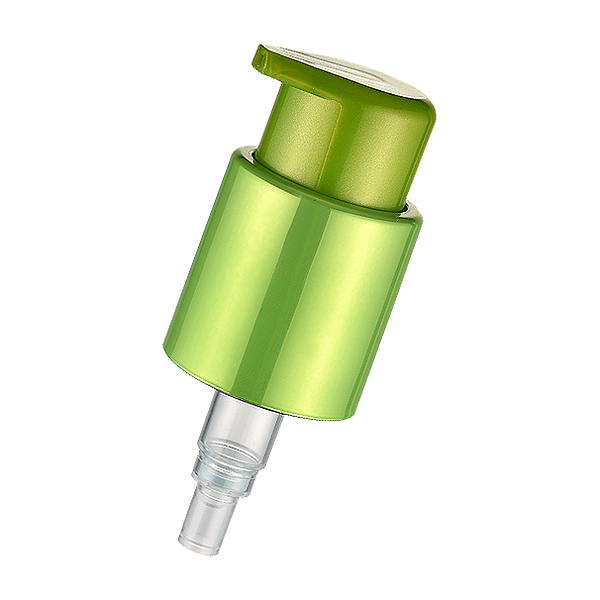

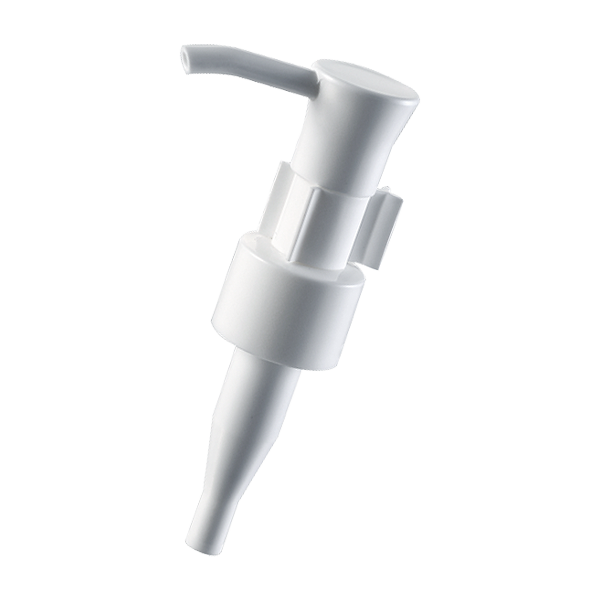

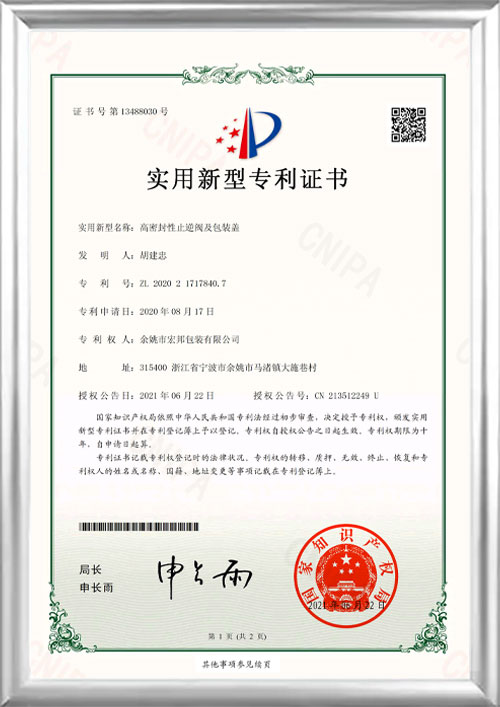

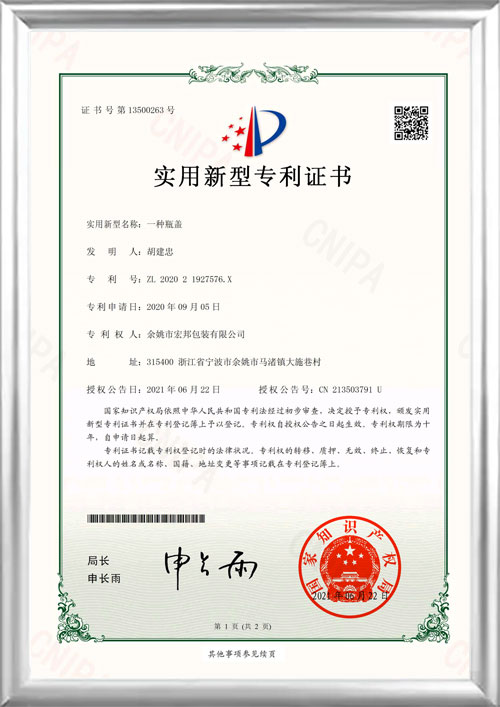

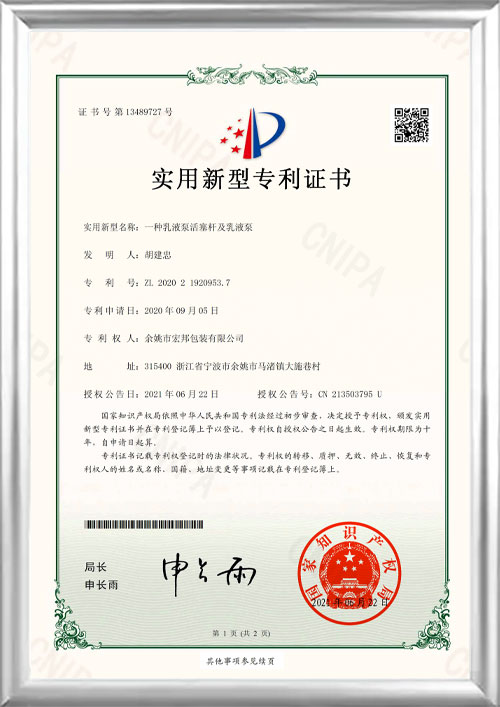

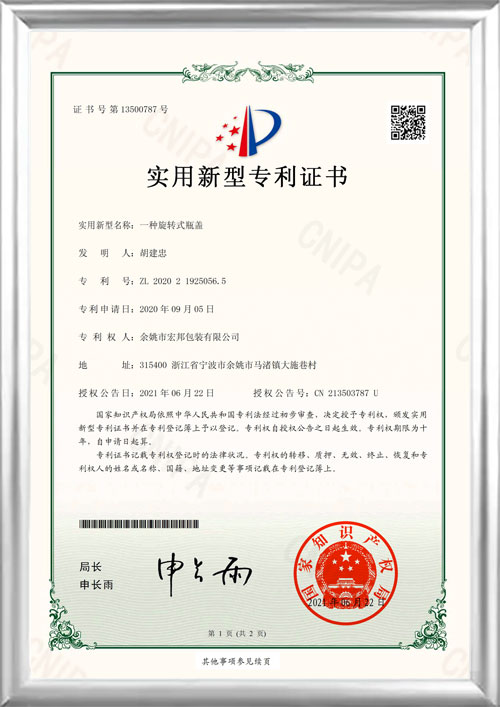

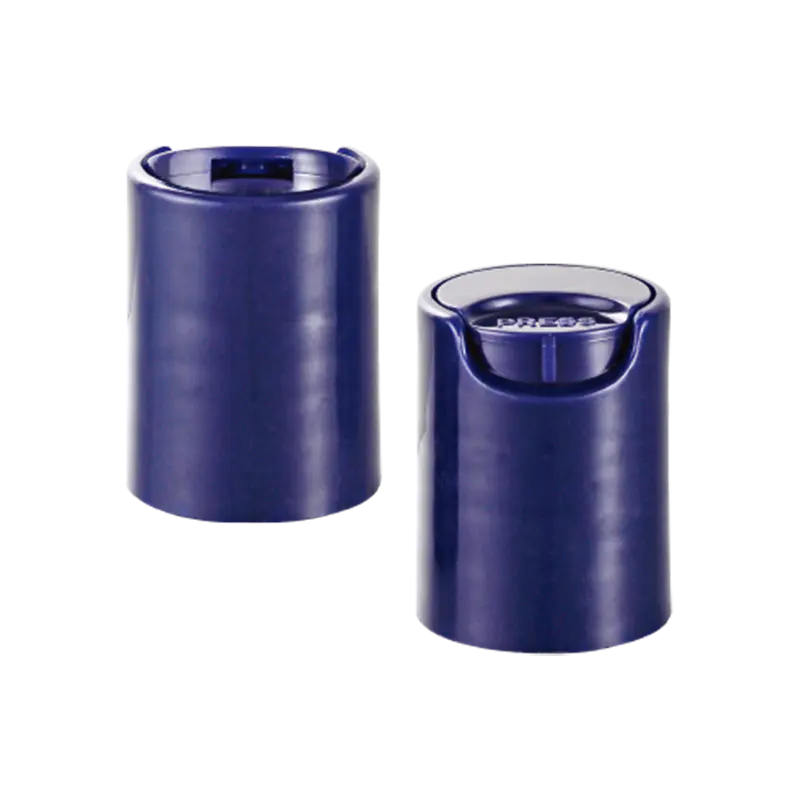

Founded in 2005, Hongbang Packaging specializes in manufacturing a wide range of plastic packaging solutions, including flip-top caps, valve caps, two-color caps, lotion pumps, and other cosmetic packaging materials. Hongbang Packaging is professional China Lotion Pump Manufacturers and Plastic Treatment Cream Pump Factory. Our products cater to various industries, including personal care, beauty, cleaning products, pharmaceutical packaging, and food packaging. We have established a comprehensive production chain that integrates product design, mold development, automated injection molding, and assembly, ensuring both high production efficiency and superior product quality.

Driven by innovation, the company is supported by a dedicated R&D team and a robust quality management system. We are committed to promoting sustainability by increasing the use of eco-friendly materials, such as PCR and TPE, to provide our clients with safe and reliable customized products.

Guided by the principle of "mutual benefit," we are focused on enhancing your brand value through innovative, high-quality, and environmentally friendly products.

Company Video

OEM / ODM SERVICE

We provide professional OEM and ODM service to meet your needs

Latest News

-

Flip Top Cap Redefines the Bottle Cap User Experience

Sep 10,2025In today's fast-paced world, consumers are increasingly demanding of product packaging, especially small design details like bottle caps, which often carry significant demands. As an innovative bottle... -

Advantages of Disc Top Caps in the Beauty and Personal Care Industry

Sep 03,2025With increasing consumer demand for beauty and personal care products, packaging design has become a key factor influencing product market performance. In this industry in particular, ease of use, pre... -

From Food Packaging to Personal Care: Plastic Caps Are Widely Used Across Industries

Aug 27,2025In modern industry, plastic caps, as a simple yet crucial packaging component, are ubiquitous in nearly every sector. From everyday food packaging to personal care, pharmaceuticals, and cosmetics, pla... -

The Ultimate Guide to Flip Top Caps: Types, Uses, and Benefits

Aug 20,2025Introduction to Flip Top Caps Flip top caps, also known as dispensing closures or hinge caps, are a ubiquitous and highly functional component of modern packaging. Their simple yet effective design al... -

The Multifunctionality of Lotion Pumps: From Traditional Cleansing to Comprehensive Beauty and Skincare Applications

Aug 13,2025With growing consumer demand for personal care, household cleaning, and beauty products, innovative packaging design has become a crucial factor in market competition. As a key component of modern pac... -

How the Treatment Cream Pump Enhances the Consumer Skincare Experience

Aug 06,2025As consumers' expectations for skincare products continue to rise, skincare brands are focusing not only on ingredients and effectiveness, but also on packaging design and user experience, becoming in...

Expansion Of Industry Knowledge About This Category

Lotion pumps play a vital role in the packaging industry, especially in the cosmetics, food, and medical industries. As consumers' requirements for convenience and hygiene continue to increase, the design and functions of lotion pumps are becoming increasingly diverse. From standard pumps, locking pumps to foam pumps, spray pumps, etc., the types of lotion pumps are constantly increasing, adapting to the wide range of market needs.

As a common type of lotion pump, the standard pump is mainly used for the precise dispensing of liquid products. By pressing the pump head, consumers can use the product conveniently and quickly. The locking pump focuses more on preventing liquid leakage and is suitable for travel and outings. It is very suitable for child care products and cosmetics containing volatile ingredients.

Foam pumps and spray pumps are widely used in the fields of cleaning and skin care. These designs enable liquids to be turned into soft foam or delicate spray, bringing consumers a better use experience. For high-end skin care brands, the packaging design using vacuum pumps and precision multi-cavity molds can further enhance the high-end feel and use of the product, while also ensuring the precise use of every drop of the product.

Yuyao Hongbang Packaging Co., Ltd., since its establishment in 2005, has been committed to providing precision lotion pump molds and packaging solutions for different industries. It has rich experience in mid-to-high-end precision molds and injection molding, and can provide customers with high-quality, short-cycle and long-life products to meet the market demand for various lotion pumps. Yuyao Hongbang Packaging Co., Ltd. produces more than 200 sets of precision molds each year, with a production capacity of more than 200 million pieces, showing its strong manufacturing strength and market adaptability.

The material selection of lotion pumps directly affects its performance, cost and market competitiveness. Lotion pumps of different materials are suitable for different product types, affecting the overall packaging quality of the product and the consumer's experience.

Plastic materials are common lotion pump materials, such as PP, PET and HDPE. These materials are not only low in cost, but also have good transparency and chemical corrosion resistance. Stainless steel lotion pumps have high durability and corrosion resistance, and are usually used for the packaging of high-end products, which can enhance the grade of the product. Glass is suitable for high-end skin care packaging, especially for brands with high packaging requirements.

Yuyao Hongbang Packaging Co., Ltd. widely uses precision multi-cavity molds and advanced injection molding processes in the production of lotion pumps. By using high-quality plastic and metal materials, the company is able to produce a variety of lotion pumps that meet the needs of different products. Yuyao Hongbang Packaging Co., Ltd.'s precision molds and injection molding technology ensure that the lotion pump has a beautiful appearance, comfortable feel, and greatly extends its service life. In addition, the company's high production capacity and technological innovation enable it to meet the strict packaging requirements of the food, medical and cosmetics industries.

In terms of environmental protection, with the increase in global environmental awareness, many lotion pump manufacturers have begun to pay attention to the recyclability and sustainability of their products. Hongbang Packaging is also committed to reducing the use of disposable plastics by adopting recyclable materials and refillable designs, which is in line with the trend of modern green packaging.

With the continuous advancement of technology, the design of lotion pump packaging should not only consider functionality, but also adapt to the needs of environmental protection and intelligence. Nowadays, more and more lotion pump designs on the market begin to focus on environmental protection, sustainability and user experience.

Environmentally friendly design has become an important trend in the industry. As the problem of plastic pollution becomes increasingly serious, many companies have begun to adopt recyclable plastics and disassembled designs to achieve an environmentally friendly cycle of packaging materials. Especially in the cosmetics, food and medical industries, lotion pumps using environmentally friendly materials are becoming more and more popular among consumers.

Yuyao Hongbang Packaging Co., Ltd., with its strong production capacity and innovative design concepts, has been at the forefront of the industry. The company not only insists on using environmentally friendly materials in the manufacturing process of lotion pumps, but also reduces material waste in the production process through precise mold design. In addition, Hongbang Packaging's multi-cavity precision mold technology and short production cycle advantages help customers stay competitive in a rapidly changing market.

In the future, as market demand diversifies, lotion pump products will not only meet traditional functional requirements, but will also incorporate more intelligent and environmentally friendly features. Yuyao Hongbang Packaging Co., Ltd. is actively promoting these innovations in order to follow the industry trend in the field of environmental protection and intelligent packaging.

English

English 中文简体

中文简体 русский

русский Español

Español